A single pump failure on a remote offshore platform can halt production for days, costing millions before the issue is even identified. Traditionally, crews relied on manual inspections and delayed reporting, often finding problems only after they escalated into costly downtime or safety risks. Multiply this across thousands of wells, pipelines, and facilities, and the scale of inefficiency becomes clear.

AI and IoT offer a different path for oil and gas software development. Together, they enable predictive, data-driven operations that anticipate failures, cut downtime, improve worker safety, and ensure environmental compliance. If you want to discover practical ways to reduce downtime, improve safety, and meet compliance, explore our IoT & AI solutions.

The role of AI and IoT in Oil & Gas

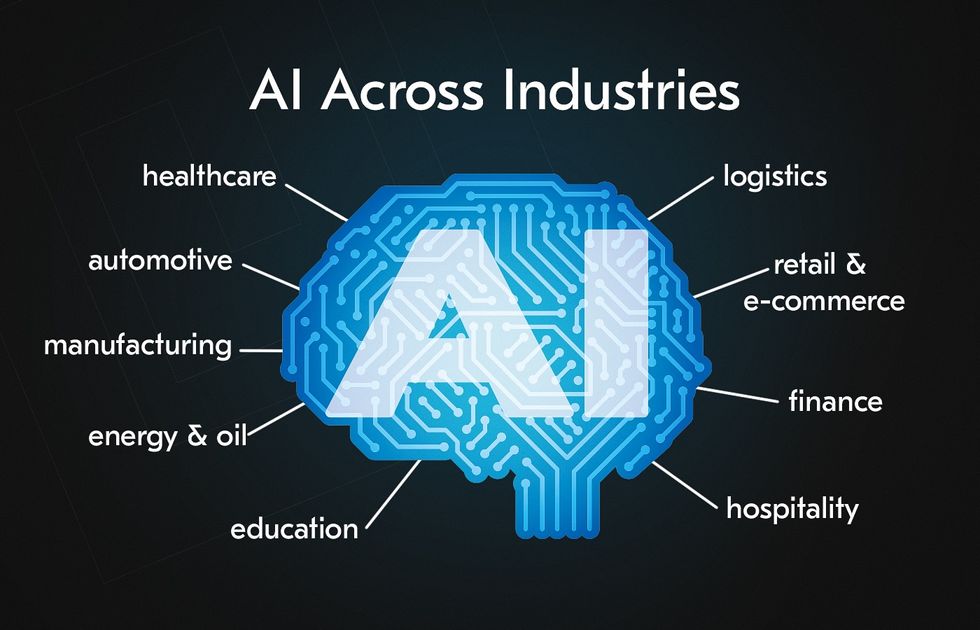

Artificial Intelligence (AI) and the Internet of Things (IoT) have become core enablers of digital transformation in the oil and gas sector. This integrated approach, often called AIoT, has proven especially valuable in an industry for efficiency, safety, and environmental compliance.

How they work together: IoT ensures continuous visibility by connecting assets, infrastructure, and personnel through networks of sensors and devices. Every critical element of the value chain, from offshore rigs and subsea wells to pipelines and refineries, becomes a source of real-time operational data. AI oil and gas then elevates this raw information into actionable intelligence, applying advanced analytics and ML to detect anomalies, predict failures, optimize production parameters, and support strategic decision-making.

What this means in practice:

Less downtime → predictive maintenance keeps equipment running.

Safer operations → workers get real-time alerts before risks escalate.

Lower costs → automation cuts waste and streamlines workflows.

Stronger compliance → continuous monitoring proves ESG and regulatory performance.

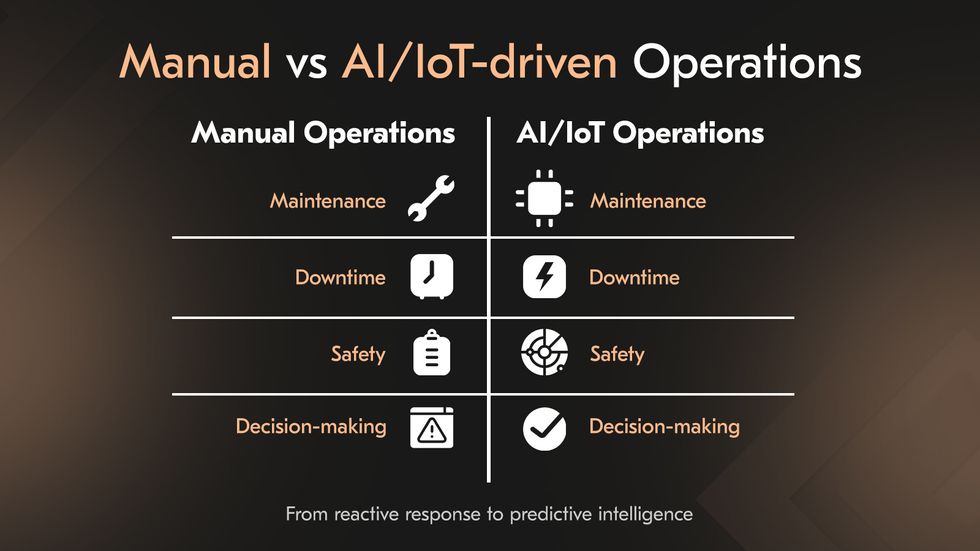

| Aspect | Manual operations | AI/IoT-driven operations |

|---|---|---|

| Maintenance | Reactive, can be fixed after breakdown | Predictive, issues flagged before failure |

| Downtime | High, often unexpected | Reduced through real-time monitoring |

| Safety | Dependent on manual checks and reporting | Continuous monitoring with instant alerts |

| Decision-making | Based on limited data, delayed insights | Data-driven, real-time recommendations |

| Compliance | Manual logs and audits, prone to errors | Automated reporting with traceable data |

| Cost-efficiency | High due to unplanned stoppages and waste | Optimised resource use, lower OpEx |

IoT oil and gas software: core capabilities

The role of IoT software development for the oil and gas industry has become the digital backbone of modern operations. Once reinforced with Artificial Intelligence and Machine Learning, these systems evolve into AIoT ecosystems that support predictive, proactive, and in some cases autonomous operations. But what exactly are the capabilities in oil and gas software development that make this possible?

The role of IoT software development for the oil and gas industry has become the digital backbone of modern operations. Once reinforced with Artificial Intelligence and Machine Learning, these systems evolve into AIoT ecosystems that support predictive, proactive, and in some cases autonomous operations. But what exactly are the capabilities in oil and gas software development that make this possible?

1. Real-time data collection and monitoring

IoT software’s foundation lies in continuous data acquisition from sensors embedded across wells, rigs, pipelines, and refineries. These sensors capture hundreds of data points every second, which together form a live operational picture. The software does more than collect information; it integrates it with control systems, often augmenting or replacing legacy SCADA infrastructure. Remote telemetry allows engineers to oversee operations at offshore fields or remote sites without physical presence, reducing exposure to risk while maintaining precision.

Acropolium designed AI-powered asset monitoring software that delivered real-time visibility into renewable infrastructure performance, environmental conditions, and compliance parameters. The platform integrated IoT sensors with advanced analytics, providing instant alerts and automated reporting to regulatory standards. This case highlights how our oil and gas engineering software solutions can extend the same logic to critical assets like pipelines and rigs, ensuring reliability, safety, and ESG alignment.

2. Predictive and preventive maintenance

IoT platforms enable a shift from reactive maintenance to predictive maintenance. By continuously analysing live sensor data, AI models detect micro-patterns that indicate early degradation. In oil and gas software development, predictive systems generate early warnings, schedule interventions at optimal times, and reduce reliance on costly emergency repairs.

3. Asset and equipment management

Oil and gas operations are asset-intensive, and IoT software provides a level of visibility that was historically impossible. Oil and gas software development company tracks assets in real time, measures their utilization and lifecycle performance. This level of transparency directly impacts operational efficiency: underused equipment can be redeployed, ageing assets can be replaced before they become liabilities, and capital expenditures can be better prioritised.

4. Safety and compliance management

Sensors monitor for gas leaks, equipment malfunctions, or environmental anomalies. While AI analytics processes these signals to detect patterns that might be invisible to human operators. In the same time, automated alerts and escalation protocols will guarantee that hazards are addressed immediately. Compliance is strengthened: data is automatically logged and mapped against industry standards, creating auditable records without manual intervention. What this means in practice is fewer regulatory breaches, reduced legal risk, and stronger ESG performance.

5. Data management and advanced analytics

Modern IoT platforms consolidate inputs from thousands of endpoints into centralised data repositories, allowing organisations to maintain a single source of truth across operations. Advanced analytics and machine learning are later applied to this unified dataset to reveal operational trends, forecast demand, and simulate production scenarios. Oil & gas software solutions like dashboards provide decision-makers with real-time KPIs, while predictive models suggest actions that prevent failures or optimise throughput.

6. Workflow and production optimisation

Once data flows and analytics are in place, IoT systems enable a closed loop of continuous optimisation. Routine workflows can be automated: inspections scheduled, inventory checked, reports generated. Production parameters are adjusted in real time based on sensor feedback, ensuring that recovery rates remain optimal while energy consumption is minimised. Even supply chains benefit, as IoT-enabled logistics track the movement of materials and equipment, identify bottlenecks, and forecast shortages before they occur.

Key benefits of AI & IoT integration in oil & gas

The impact of oil & gas software solutions is already visible in four areas that will shape the industry’s competitiveness in the years ahead. Are you capturing these advantages?

Leverage predictive maintenance & reduced downtime

Equipment failures disrupt production, compromise safety, and trigger cascading costs far beyond the immediate repair. Sensors embedded in pumps, compressors, turbines, and drilling equipment generate continuous data streams on vibration, temperature, pressure, and fluid dynamics. AI models process these signals in real time, identifying patterns that indicate early-stage wear or hidden anomalies. The oil & gas software solutions contribution is measurable. Digital twin platforms with AI have cut unplanned downtime by 20–30%.

Enhance worker safety through real-time alerts

AI and IoT strengthen safety systems in providing real-time visibility into environmental conditions and worker well-being. Their networks of sensors installed across platforms and facilities continuously track variables such as gas concentrations, pressure fluctuations, and equipment performance. AI-driven analytics and other oil & gas software solutions interpret this data instantly, generating alerts when thresholds are breached.

AI-powered safety systems are helping operators lower incident rates, with early deployments showing fewer recordable safety events in hazardous environments. The cumulative effect is a safer working environment and human exposure to danger is significantly reduced.

Reduce cost & optimize resources

In drilling, AI algorithms evaluate parameters such as weight on bit, mud flow, and revolutions per minute, reducing non-productive time and lowering operational costs per well. Reservoir management benefits from advanced analytics that optimise extraction rates and recovery factors. Moreover, AI-driven exploration tools in oil and gas software development reduce site selection errors, cutting exploration costs and accelerating time-to-production.

Benefit from sustainability & emission monitoring

AI and IoT provide the technical foundation for meeting these expectations while reducing ecological risk. Continuous emissions monitoring systems, powered by IoT sensors, track methane, CO₂, and other pollutants across assets. After AI algorithms analyse these datasets in real time. This proactive capability is critical when methane emissions are under intense scrutiny, given their disproportionate contribution to global warming. Automated reporting platforms, meanwhile, streamline compliance by producing regulator-ready documentation and reducing the cost of ESG disclosures.

Popular AI oil and gas use cases in 2025

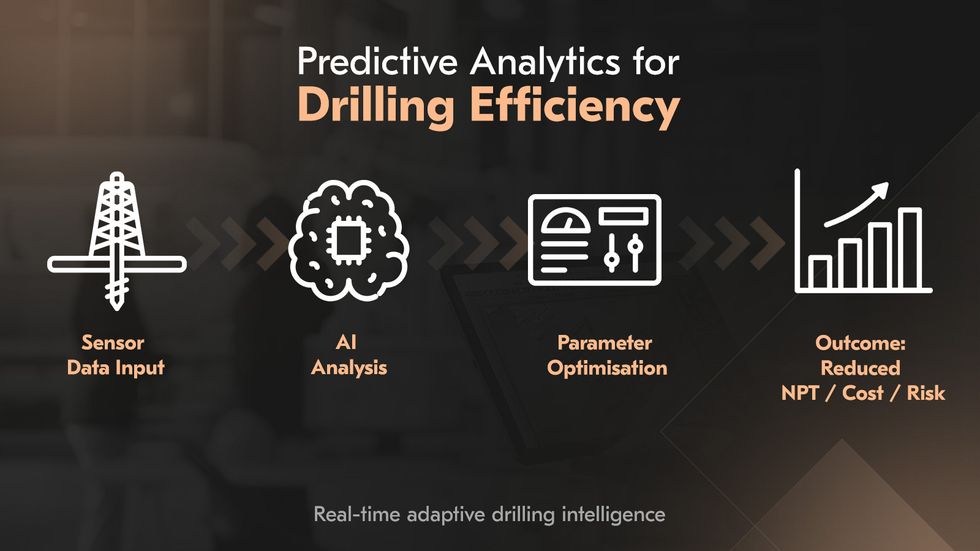

Use case: Predictive analytics for drilling efficiency

AI-driven predictive analytics maximise penetration rates and minimise downtime. Instead of relying solely on fixed drilling models, operators now use adaptive AI systems that adjust parameters continuously as new data flows in from downhole sensors.

AI-driven predictive analytics maximise penetration rates and minimise downtime. Instead of relying solely on fixed drilling models, operators now use adaptive AI systems that adjust parameters continuously as new data flows in from downhole sensors.

Drilling parameter optimisation: Machine learning algorithms fine-tune the weight on bit, revolutions per minute, and fluid flow rates in real time to improve the rate of penetration.

Reduced non-productive time (NPT): Predictive optimisation reduces operational delays and inefficiencies, cutting drilling costs and accelerating project timelines.

Exploration and site selection: Geological intelligence systems powered by Artificial Intelligence software development for oil and gas analyze seismic and historical drilling data to improve site selection, reducing exploration costs and boosting success rates.

Reservoir insights: AI models assist in analysing geological structures and drilling supervision, enabling better reservoir understanding and reducing risks associated with misdrilling.

Use case: Real-time monitoring of equipment health

Equipment failures in offshore and remote operations have severe financial and safety implications. IoT sensors connected to AI platforms provide continuous monitoring.

Equipment failures in offshore and remote operations have severe financial and safety implications. IoT sensors connected to AI platforms provide continuous monitoring.

Predictive maintenance: AI analyses sensor data (temperature, vibration, flow rates, and pressure) to forecast potential failures before they occur.

Critical asset focus: Electrical Submersible Pumps (ESPs), compressors, and turbines are continuously monitored, with AI models detecting anomalies like voltage instability or gas locking.

Autonomous diagnostics: Next-generation systems are moving toward self-diagnosing and adaptive operation capabilities, reducing reliance on human intervention.

Downtime reduction: Predictive maintenance decreases unplanned outages and extends the life cycle of mission-critical assets.

Use case: Automated anomaly detection

In 2025, automated anomaly detection is widely used to maintain operational safety, prevent failures, and secure digital infrastructure.

Operational monitoring: AI evaluates data from pumps, valves, and compressors, spotting anomalies in vibration, temperature, or pressure that indicate early signs of failure.

Cybersecurity protection: Machine Learning models monitor data streams for abnormal patterns, detecting cyber intrusions or system manipulations in real time.

Environmental compliance: Algorithms identify abnormal emission levels or equipment malfunctions.

Fault pattern recognition: Historical operational data trains AI systems to recognise patterns that precede failures.

Use case: Supply chain optimisation

The oil and gas supply chain is vast, global, and complex. AI, enhanced by IoT tracking, is being deployed to make logistics and inventory management smarter, faster, and more cost-efficient.

Logistics and material tracking: IoT devices monitor the movement of parts, machinery, and raw materials throughout the supply chain.

AI-powered forecasting: Predictive analytics models anticipate demand fluctuations, enabling more accurate procurement and distribution planning.

Inventory management: Automated systems use ML to balance stock levels, reducing excess inventory and preventing shortages.

Cost and efficiency gains: Big data analysis of transportation routes, weather conditions, and demand patterns delivers tangible cost savings.

Practical IoT oil and gas software use cases

Below are some of the most impactful IoT and AI-driven use cases in the industry:

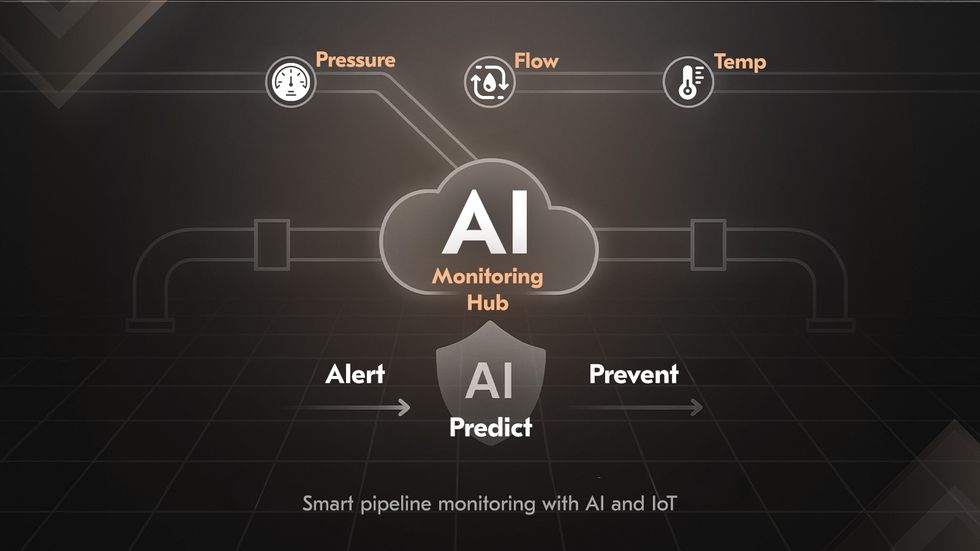

Use case: Smart pipeline monitoring

Continuous monitoring with IoT sensors allows operators to anticipate failures, optimise throughput, and maintain regulatory compliance. When paired with AI, monitoring systems evolve into predictive platforms capable of real-time modelling of corrosion rates, flow dynamics, and asset health.

Real-time condition tracking: Sensors capture pressures, temperatures, and flow rates to identify early warning signs of deterioration or inefficiency.

SCADA system enhancement: IoT integration extends traditional SCADA platforms with remote telemetry, automated alerts, and control capabilities for compressors, pumps, and tanks.

Predictive integrity management: AI algorithms forecast corrosion or blockages, reducing the probability of catastrophic pipeline failures.

Operational simulations: Digital platforms support hydraulic simulations to plan and optimise pipeline operations more effectively.

As an oil and gas software development company, we developed a custom oil and gas analytics software solution that consolidated sensor data from pipelines and drilling equipment into a unified monitoring system. The platform used AI models for anomaly detection and predictive maintenance, reducing downtime and enabling early leak prevention.

Use case: Sensor-based leak detection

Leaks in oil and gas infrastructure have financial and environmental consequences. IoT systems minimise these risks by detecting and addressing anomalies before they escalate.

Anomaly detection: Pressure and acoustic sensors continuously monitor infrastructure for deviations that indicate leaks or ruptures.

Automated leak identification: AI-based leak detection platforms quickly confirm and locate issues to guide maintenance teams.

Instant alerting and shutdown: Edge oil and gas engineering software solutions trigger automated valve closures and send alerts to mobile devices to contain incidents immediately.

Use case: Workforce tracking & safety compliance

In high-risk environments, safety cannot rely solely on manual processes. IoT-enabled systems enhance oversight of worker conditions, compliance, and incident response. Oil and gas software development company can offer protection to employees with strict industry safety regulations.

Real-time safety monitoring: Sensor networks track hazardous conditions and equipment performance to prevent accidents.

Hazard and anomaly detection: AI analyses sensor and camera data to identify unsafe behaviours or potential risks.

Workforce tracking and certification: IoT tools verify worker authorisations and monitor headcounts for accurate evacuation planning.

Incident management and response: Digital safety systems log incidents, recommend corrective actions, and automate risk assessments.

Use case: Environmental monitoring

IoT and AI technologies provide the continuous monitoring and automated reporting needed to meet increasingly strict ESG obligations. These oil and gas software application development solutions help operators reduce environmental risk, avoid penalties, and strengthen trust with regulators and investors.

Continuous emissions monitoring: IoT sensors track methane, CO₂, and other emissions across assets and facilities.

Compliance automation: AI-driven platforms compile and submit regulatory reports, reducing administrative burdens and error rates.

Environmental risk prevention: Predictive models identify conditions likely to cause spills or emissions breaches.

Integrated impact tracking: Advanced platforms measure water and soil quality to give a complete picture of environmental impact.

Challenges in implementing AI and IoT in oil and gas

Legacy infrastructure integration

One of the most persistent barriers is the industry’s dependence on outdated control systems. Many Supervisory Control and Data Acquisition (SCADA) platforms today were not designed to connect with modern analytics clouds or advanced security protocols. The result is critical operational information remains siloed and interoperability becomes prohibitively complex.

Cybersecurity risks

The convergence of operational technology (OT) with IT introduces vulnerabilities that traditional security measures cannot fully address. State-backed actors and organized cybercriminals increasingly target energy infrastructure because of its systemic importance, while cyber-insurance for real-time edge environments remains patchy at best.

High initial investment

Digital transformation within oil and gas software development services is capital-intensive. Deploying IoT sensors across fields, upgrading networks, and implementing cloud and edge infrastructure require significant upfront spending. The business case often stalls on ROI visibility. While predictive maintenance or digital twins may deliver long-term value, the immediate returns are harder to quantify, especially in low-price cycles.

Workforce digital skills gap

Even the best-designed AI and IoT systems fail without the people to operate, interpret, and maintain them. The oil and gas workforce faces a dual challenge: many experienced employees are nearing retirement, while the industry struggles to attract younger digital talent competing with the tech sector.

Best practices for successful deployment

Design a phased integration strategy

Rolling out AI and IoT in upstream or midstream operations cannot be done in one sweep. The financial stakes are high, and legacy systems are deeply embedded in daily workflows. That is why a phased approach is the most effective path forward. Oil and gas software development services begin with narrowly defined use cases that prove value in controlled conditions. Once validated, these solutions can be scaled through staged rollouts and rigorous testing to minimise disruption. The real differentiator comes after launch: continuous monitoring, model recalibration, and feedback loops ensure that solutions stay accurate, resilient, and aligned with evolving operational realities.

Apply a cloud and edge computing approach

Oil and gas operations generate massive volumes of sensor data; not all can wait to be processed in the cloud. The cloud delivers scalability and analytical depth, providing centralised data lakes, orchestration tools, and advanced machine learning capabilities. At the same time, edge systems process mission-critical data onsite, enabling instant responses even in offshore or remote environments.

Partner with a vendor

The complexity of AI and IoT demands expertise that spans drilling, engineering, data science, and cybersecurity. This is why oil and gas software development company partnerships are helpful and strategic. And here’s the critical point: companies need a clear build-versus-buy strategy. Knowing which capabilities to outsource and which to retain in-house ensures control over sensitive processes while still accelerating innovation with external expertise.

Comply with industry regulations

Compliance must be embedded into digital solutions from day one. AI and IoT now enable tracking emissions, equipment health, and worker safety in real time, automatically generating reports that once required weeks of manual effort. Expanding IoT networks increases the cyber-attack surface, making strong encryption, intrusion detection, and continuous monitoring indispensable.

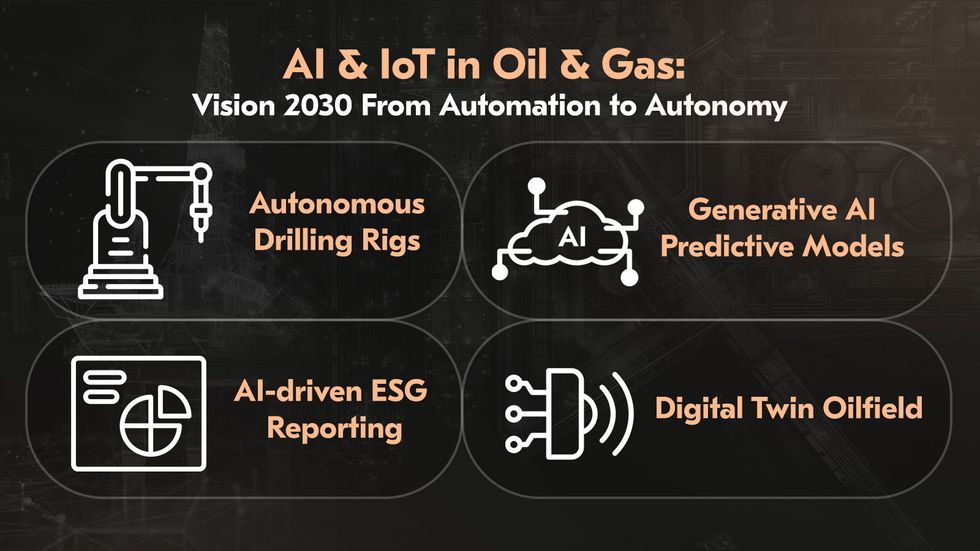

Future outlook on AI & IoT in oil & gas by 2030

Rise of autonomous drilling rigs

Autonomous drilling is moving from pilots into scaled deployment, with AI and robotics enabling operations that reduce human exposure to high-risk environments. Robotics will extend beyond drilling into inspection, maintenance, and logistics. The long-term goal is the autonomous oilfield, where AI-driven systems can execute, monitor, and adapt operations without direct human intervention.

Generative AI for predictive modelling

Generative AI and advanced machine learning models are set to elevate predictive analytics across exploration, drilling, refining, and trading. Unlike traditional models trained on narrow datasets, generative AI can create synthetic geological, operational, and market scenarios, improving risk assessment and decision-making.

In one of our partnerships, we also built an AI-driven renewable energy platform that forecasted generation, automated maintenance scheduling, and optimised resource allocation across distributed assets. While developed for renewables, the solution demonstrates Acropolium’s expertise in AI software development oil and gas, especially in predictive modelling and decision support.

AI-driven ESG reporting

AI-driven platforms automate the capture, verification, and reporting of environmental data, from methane leaks to carbon intensity metrics, with precision unattainable through manual processes. Regulatory frameworks in the US and EU will require continuous emissions monitoring and transparent ESG disclosures. Deploying AI and IoT together is expected to reduce compliance costs by as much as 20–30%, while enabling companies to demonstrate measurable progress on sustainability and build investor trust.

Digital twins for full-field optimisation

Digital twins evolve from asset-specific replicas into full-field, continuously updated virtual environments. These systems integrate real-time IoT data with simulation models to test operational strategies, predict failures, and optimise entire production systems. Early adopters such as Shell and BP have reported billions in annual savings from digital twin deployments, with downtime reductions of up to 30%.

If you want to explore how AI and IoT can accelerate efficiency, safety, and sustainability in your operations, our experts can help. Book a consultation or schedule a demo solution to see how these technologies can be applied to your business.