- Software Development

- AI & ML

- Data Analytics

- Platform Development

- Real-Time Solution

- Big Data

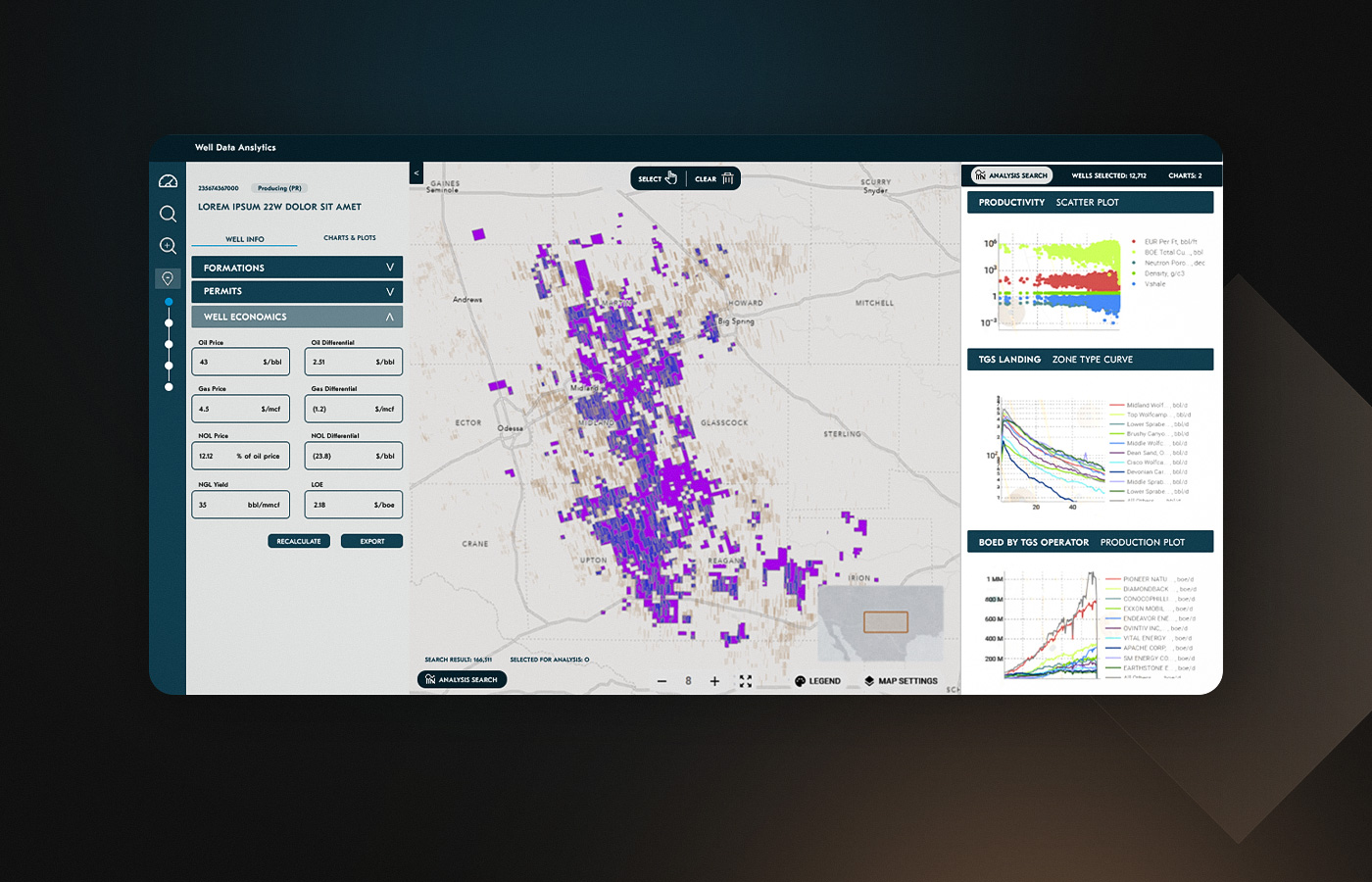

An international mining company was looking for oil and gas analytics software that could bring together data from SCADA systems, IoT sensors, and drilling logs. What we introduced was a real-time predictive platform. It resulted in 15% higher production efficiency, 20% lower downtime, and a 30% decrease in maintenance costs.

client

NDA Protected

USA

130 employees

With major stakes in exploration, drilling and production, our client is a world leader in the oil & gas sector. Additionally, it maintains operations throughout the continent(s) of Europe and South America and in other countries with offshore production facilities, onshore wells, production fields, and reservoirs.

request background

Oil and Gas Analytics Software to Boost Efficiency with Informed Decisions

The customer was in need of analytics software to solve the problem of operational inefficiencies due to data being scattered across disparate sources. Different monitoring and reporting systems were in place at all the sites. Engineers found it difficult to get a comprehensive view of how well everything was working across all operations worldwide. Without integrated data management, the firm lost out on drilling optimization and preventive maintenance. The implementation of oil and gas analytics became critical for maintaining competitive advantage in volatile market conditions.

Increased market volatility and regulatory pressures required more cost discipline. Equipment failures caused expensive downtime. Panchromatic prediction models resulted in unreliable estimates of production. Leadership wanted something they could act on to make decisions and take action fast. Effective management of data across drilling sites and production facilities became essential for operational visibility.

challenge

A Scalable Platform with Comprehensive Oil and Gas Analytics

Disparate data from SCADA, IoT, and drilling logs. Each geographical location used different monitoring systems. SCADA platforms tracked equipment status, IoT sensors measured environmental conditions, and drilling logs contained geological information. These sources operated independently with no integration. Engineers spent days compiling reports manually. Legacy SCADA integration limitations prevented unified operational visibility.

No unified approach to data management, creating critical data gaps across operations. Historical production records sat in legacy databases. Real-time streams are never connected to analytical tools. The company lacked a centralised repository where teams could access complete information. This fragmentation delayed decision-making and obscured performance trends.

Low estimation accuracy. Production planners relied on spreadsheets and historical averages. These methods failed to account for reservoir behaviour changes or equipment degradation. Prediction errors led to missed production targets and inefficient resource allocation. Without proper oil and gas analytics capabilities, the company struggled to optimize resource allocation effectively. Forecasting accuracy remained below 60% without advanced analytical models.

Equipment downtime risks. Reactive maintenance meant fixing equipment after failures occurred. Unscheduled production interruptions and associated loss of revenue occurred. The company had no way to know when key components would fail.

Compliance and regulatory requirements. The oil and gas industry faces strict reporting obligations. Without proper management of data and audit trails, demonstrating compliance became labour-intensive. Security concerns around sensitive operational data added complexity. Missing cloud scalability prevented efficient multi-site operations.

goals

- Integrate multiple SCADA systems, IoT sensors, drilling logs and production databases in one platform. Facilitate real-time data travel from offshore rigs, onshore wells and refineries located in different continents. Broader data integration to ensure ubiquitous distribution of data, transforming from disparate formats and locations into a single source of truth for all operational metrics and KPIs.

- Advanced algorithms analyze equipment vibration, temperature and pressure to forecast failures before they happen. Develop models that use information on past patterns of failures and/or maintenance records to determine the optimal time for an intervention. Facilitate proactive decision-making by issuing early warning alerts of potential problems so that teams can plan for preventive maintenance during scheduled downtime instead of emergency breakdowns.

- Build advanced prediction engines that process geology surveys, seismic data, and historical production to output optimal drilling locations and depths. Developed reservoir simulation models for pressure variations, fluid transport, and rock permeability to optimize extraction. Access a more accurate view of production potential by integrating real-time drilling parameters, formation attributes, and equipment performance data management with detailed analytics.

- Architect cloud native infrastructure that can scale with the exponential growth of data coming from new wells and facilities. Construct modular aspects that you may scale separately when computational needs arise. Make sure the stack can run on newer tech, such as edge processing and 5G connectivity, but still perform in more traditional environments. Facilitate geographical expansion without full local infrastructure redesigns or large investments.

- Turn complex operational data into rich, visual graphical displays to aid decision making at all levels of your organisation. Develop dedicated views for roles like engineers, geologists, managers and executives with related KPI’s & Metrics. Enable out-of-the-box viewing of high-level summaries and the ability to drill-down right down to equipment-level stats. Automate report creation and distribution with the ability to customize alerts for key thresholds or unusual activity.

- Adopt homogeneous data governance rules and policies for uniform metrics and calculations within all operations. Create detailed audit trails to support regulatory reporting and compliance validation. Implement industry-leading security features such as encryption, access restrictions and threat monitoring to safeguard sensitive operational and geological information.

solution

The Ultimate Tool for Real-Time Oil and Gas Analytics

.NET, ASP.NET Core, React.js, Redux, D3.js, PostgreSQL, Apache Hadoop, Apache HBase, AWS, EC2, S3, RDS, Redshift, Apache Kafka, Apache Spark, TensorFlow

19 months

9 specialists

We built robust analytics software that collects and processes disparate data streams using advanced analytical tools. Integrated in real-time with SCADA systems, drilling logs, IOT and production records using Apache Kafka and Apache Spark. This creates a unified repository supporting sophisticated analysis. Comprehensive SCADA integration protocols ensure seamless data flow from all equipment types.

With TensorFlow training, drilling can be optimized and equipment maintained using predictive analytics models. The forecasting engine examines reservoir data to forecast production rates and determine optimal drilling parameters. The recommendations to the engineers operate off current conditions and historical patterns. The prediction engine leverages historical patterns and real-time conditions for superior precision. Advanced reservoir data modeling provides accurate production potential assessments.

The platform architecture emphasises cloud scalability using AWS services. Storage layers accommodate massive data volumes while analytical processing scales dynamically with workload demands. This approach supports operations across multiple continents without performance degradation. Our data management architecture provides transparent integration combined with best practices for securely managing and accessible the data.

React.js and D3.js power the visualisation layer. Custom dashboards present complex information clearly to engineers, geologists, and managers. Real-time monitoring displays update continuously, while reporting tools generate exports in CSV and PDF formats. Real time monitoring capabilities track equipment performance continuously across all facilities. Customizable reporting dashboards provide role-specific insights for different stakeholders.

- We constructed a flexible architecture with improved cloud scalability designed for handling large-scale data from IoT sensors and SCADA points of integration, enabling the system to be easily expanded in the future and allowing long-term growth. The platform's data management infrastructure processes terabytes of operational information daily while maintaining optimal performance across global operations.

- Our engineers developed compliance and security frameworks that allowed for industry standardization in the energy space with the selected architecture. Natively-integrated compliance and security capabilities support regulatory requirements, safeguard sensitive operational data, and retain complete audit trails for oil and gas analytics workloads. Writing the security protocols monitor real-time discourages unsuitable access to valuable reservoir data and production systems.

- Sophisticated predictive analytics were used to predict equipment failures, which led to significant decreases in maintenance costs and downtime as a result of intelligent preventive maintenance planning. Preventive maintenance scheduling minimises the rate of equipment failure based on patterns from IOT instrumentation and historical data. It also allows for drilling optimization by forecasting the best maintenance windows with minimal production interruption.

- Architected according to machine learning best practices, the analytics software solution offered actionable insights for engineers and geologists using advanced prediction models to enhance asset management while promoting well-informed decision making. Complements SCADA with integration to current SCADA systems, meters are used and monitored in unison for all data monitoring, allowing reporting dashboards to show real-time operational details immediately.

- By designing the solution with modular cloud scalability in mind, we made it as flexible to the changing business requirements and new technologies. It has stood the test of time. The flexible data management framework accommodates new drilling optimization techniques and emerging reservoir data analysis methods as industry standards evolve.

- Focused on convenient user flow, Acropolium developed an intuitive UI with React.js and D3.js to present complex analytics data and insights effectively to users. Customizable reporting dashboards provide role-based views while real time monitoring interfaces track critical metrics across all operational areas from drilling to production.

- Lastly, we conducted extensive testing to ensure reliability, accuracy, and performance of all forecasting algorithms and predictive analytics models, followed by iterative optimizations. Testing validated SCADA integration protocols, IoT sensors connectivity, and compliance and security measures across diverse operational scenarios.

outcome

Optimized Workflows & Cost Savings through Advanced Analytics in Oil and Gas Analytics Operations

- 15% increase in production efficiency. Better prediction of sights and drilling optimization reduced the time to reach production targets. Engineers applied data-driven recommendations that improved well performance. Resource allocation became more effective across the portfolio. Drilling optimization algorithms improved penetration rates by 25%.

- 20% reduction in equipment downtime. Predictive analytics identified potential failures before they occurred. Maintenance teams performed preventive maintenance during scheduled windows. Unplanned outages decreased significantly, improving production consistency. Real time monitoring reduced incident response time by 45%.

- 30% cost savings in maintenance. Shifting from reactive to preventive maintenance reduced emergency repair expenses. Longer equipment life cycles lowered replacement costs. Better planning minimised overtime labour charges.

- Improved forecasting accuracy. Reservoir data analysis and machine learning models produced more reliable production estimates. Planning teams were able to make smarter decisions with respect to capital investments and operational tactics. The forecasting error rate was reduced by more than 40% versus other approaches.

- Enhanced transparency for leadership. Managers had a bird's-eye view of operations with consolidated dashboards from all locations across the globe. They were able to isolate underperforming assets sooner and deploy resources more strategically. Data management capabilities supported faster decision-making at all organisational levels. Interactive reporting dashboards improved decision-making speed by 35%.

- Streamlined data management processes reduced report generation time by 50%. Cloud scalability enabled seamless expansion to new production sites. IoT sensors network provides granular operational data for continuous optimization.

client feedback

We are thrilled with the new software. Acropolium’s agility and taking care of details have empowered us with the operational intelligence to be more efficient and reliable than ever. Now, we run even more smoothly and are squeezing all the power out of data, while saving costs.