Construction remains one of the most data-intensive industries, yet much of that data arrives too late to influence outcomes. Design models, schedules, procurement records, equipment telemetry, and site imagery exist in parallel rather than in concert. Project managers spend significant time reconciling information instead of acting on it. Decisions are often made with partial visibility, while critical patterns remain hidden across disconnected systems.

Artificial intelligence addresses this structural gap. By learning from historical performance and continuously processing live inputs, AI systems surface emerging risks, forecast likely outcomes, and support adjustments while there is still room to respond. Planning becomes adaptive rather than fixed, and oversight becomes continuous rather than episodic.

The growing interest in AI reflects pressure that traditional methods can no longer absorb. Projects are larger, margins are tighter, labor is scarcer, and compliance demands are higher. Under these conditions, incremental process improvements are insufficient. What changes is how uncertainty is managed across design, delivery, and operation.

If you are assessing how AI can be applied within your construction processes, from planning and cost control to site execution and asset management, Acropolium can support that evaluation with practical, implementation-focused construction development and AI expertise. Contact us to discuss how your data, systems, and workflows can be prepared for AI-driven construction operations.

In this article, we will guide you through:

what AI means in the context of construction

how AI is changing established construction processes

how to use AI in construction: the most impactful applications

measurable benefits construction teams achieve by applying AI in real projects

key challenges of AI adoption and proven mitigation strategies

real-world case examples of Artificial Intelligence in construction

future directions for AI for construction

What is AI in construction industry?

AI in the construction industry refers to a growing class of digital systems that can learn from data, interpret complex environments, and support decisions that were traditionally made through manual analysis and experience. It spans software, analytics, and intelligent machinery that operate across design offices, jobsites, and asset operations. The key change lies in expanding how information is processed and acted upon when projects involve thousands of variables moving at once.

Despite growing attention, AI adoption across construction remains uneven. Recent surveys show that 45% of companies have no AI implementation at all, while another 34% are limited to early pilots, and less than 1% have embedded AI across the organization.

Why does this matter now? Construction has long depended on static plans and delayed feedback. Schedules are often updated after disruptions occur. Costs are reviewed once overruns are already visible. Safety management systems issues surface only after incidents are reported. AI changes that sequence by turning data into early signals. Instead of asking what went wrong, teams can ask what is likely to happen next and what action should be taken before impact accumulates.

Core technologies behind construction AI

Artificial Intelligence in construction industry is built from several complementary technologies, each addressing a different class of problems.

Machine Learning represents the analytical backbone. Models trained on historical project data identify patterns in productivity, delays, equipment performance, and cost variance. When similar conditions arise on a new project, predictions are generated automatically. How long before a crane failure becomes likely? Which subcontractor scopes historically overrun budgets? ML and AI services provide probabilistic answers rather than assumptions.

Generative AI extends beyond prediction into creation. When design teams define constraints such as budget limits, spatial requirements, or regulatory rules, generative systems produce multiple design or planning alternatives in parallel. What options meet both cost and constructability requirements? Which layout minimizes material waste while meeting code? Exploration that once took weeks becomes part of early planning.

Computer vision allows AI systems to interpret visual input from cameras and drones. Jobsites generate vast amounts of visual data every day. Who is wearing protective equipment? Which areas lag behind schedule? How closely does as-built work align with the model? Vision-based systems evaluate these conditions continuously rather than through periodic walkthroughs.

Natural language processing focuses on unstructured information. Construction projects produce contracts, specifications, RFIs, and daily reports at scale. NLP systems extract key obligations, identify inconsistencies, and summarize changes. Instead of reading hundreds of pages to find a clause or dependency, teams receive targeted insight when it matters.

Robotics applies intelligence to physical execution. Autonomous and semi-autonomous machines handle repetitive or hazardous tasks while generating operational data. Where human labor faces safety or fatigue limits, robotics provides consistency and measurable performance.

AI across the construction lifecycle

AI does not operate in isolation at a single project phase. Its functionality grows when applied across the full lifecycle.

During pre-construction, AI supports feasibility analysis, site evaluation, and early cost modeling by correlating location data, historical outcomes, and design constraints. Planning decisions benefit from earlier insight into risk and constructability.

During construction, AI supports coordination by automating reporting, updating schedules as conditions change, and monitoring execution through sensors and visual data.

After handover, AI-enabled digital twins connect operational data back to the original design intent. Asset performance, energy consumption, and maintenance planning are informed by continuous feedback rather than periodic inspection.

How AI is changing traditional construction processes

For decades, construction processes relied on static plans, delayed reporting, and human coordination across highly variable environments. AI introduces a different operating model, one where live data from design models, jobsites, equipment, and supply chains inform decisions. The impact extends to how projects are planned, monitored, adjusted, and governed across the full lifecycle.

From design to pre-construction workflows

Design and pre-construction have traditionally depended on sequential iterations driven by expert judgment and manual recalculation. AI introduces constraint-based generation, where design options are evaluated simultaneously against cost, constructability, regulatory requirements, and performance criteria. Generative design tools allow teams to explore a broader solution space early, reducing late-stage redesign driven by feasibility gaps.

BIM construction workflow automation also changed in character. Quantity extraction and cost estimation move from episodic manual takeoffs to continuous recalculation. AI-enabled 5D BIM environments automatically update quantities and cost projections as models evolve, improving alignment between design intent and financial feasibility long before construction begins.

From static planning to adaptive scheduling

Traditional construction schedules assume stable conditions and rely on manual updates when deviations occur. AI-driven scheduling replaces this assumption with adaptive planning models that absorb change as a constant factor. Inputs such as weather forecasts, delivery status, labor availability, and construction site monitoring progress are analyzed continuously rather than reviewed after delays materialize.

Scheduling becomes a forecasting discipline rather than a reporting exercise. AI systems simulate downstream impacts of disruptions and propose adjustments before crews are affected, supporting more stable sequencing and reduced idle time across trades.

From manual work to automation and robotics on the jobsite

Field execution is changing as automation expands beyond isolated equipment into coordinated site operations. Autonomous and semi-autonomous machinery now supports grading, material movement, and repetitive assembly tasks with consistent precision. Robots handle hazardous or physically demanding tasks, while drones and mobile robots collect high-frequency site data to verify progress.

Manual walkthroughs and visual inspections are increasingly supplemented by computer vision and spatial analysis, allowing site conditions to be compared against design models with greater accuracy and consistency.

From risks to proactive safety and risk control

Safety management has historically relied on training, signage, and post-incident review. Artificial Intelligence in the construction industry introduces continuous monitoring and early detection. Computer vision systems analyze live video feeds to identify unsafe behavior, missing protective equipment, or restricted zone access in near real time. Wearable devices enhance contextual awareness by tracking proximity to machinery and physiological indicators associated with fatigue or heat stress.

Risk management also becomes predictive. By correlating historical incident data with current site conditions, AI highlights elevated risk periods and activities, allowing targeted preventive measures rather than generalized safety interventions.

From static systems to predictive maintenance and automated documentation

Equipment management evolves from fixed maintenance schedules and reactive repair. Sensors embedded in heavy machinery stream performance data that AI models analyze to detect early signs of degradation. Maintenance activities across construction Artificial Intelligence can be planned around project schedules, reducing unplanned downtime and extending asset life.

Predictive maintenance supported by sensor data and ML contributes to broader automation efforts. According to Boston Consulting Group, up to 30% of construction tasks could be automated or partially automated.

Administrative processes undergo similar change. Artificial Intelligence in construction project management automates large portions of documentation handling, including RFIs, daily logs, and contract analysis. Information flows more quickly between the site and office, reducing reporting delays and manual reconciliation.

| Process area | Traditional approach | AI-driven approach |

|---|---|---|

| Design | Manual iterations and late feasibility checks | Constraint-driven generative design |

| Cost planning | Periodic manual takeoffs | Continuous 5D BIM-based estimation |

| Scheduling | Static plans updated after delays | Adaptive, data-driven recalibration |

| Safety | Manual inspections and incident reports | Real-time monitoring and prediction |

| Site execution | Labor-intensive and reactive | Robotics and autonomous data capture |

| Maintenance | Reactive or time-based servicing | Predictive, condition-based project planning optimization |

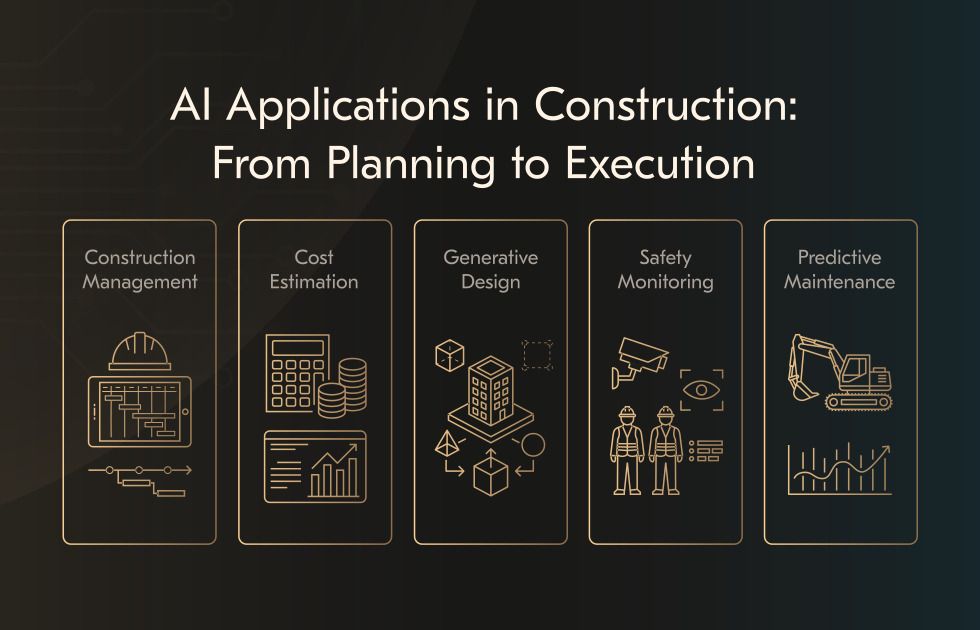

Key applications of AI in construction

AI in construction management

AI strengthens construction management by converting fragmented operational signals into continuously updated guidance for scheduling, coordination, and execution control. Automated handling of documentation, RFIs, and progress tracking reduces reporting latency and improves alignment between site activity and management decisions. One of the applications of Artificial Intelligence in construction management is dynamic planning models that adjust timelines and resource deployment as conditions change.

In practice, this capability translates into the following operational improvements:

Automated reporting, documentation, and RFI workflows

Dynamic scheduling based on live site and external data

Optimized labor and equipment allocation across trades

AI for cost estimation and management

AI in construction estimating replaces static estimates with living financial models that adjust as designs, market conditions, and project realities change. Quantity extraction from BIM models shifts from episodic to continuous, while cost exposure is assessed based on historical performance, supplier behavior, and contract structures. Budget control transforms from post-fact review to early detection of variance drivers.

In practical terms, this approach enables the following cost-control mechanisms:

Automated takeoffs and 5D BIM cost recalculation

AI-driven construction analytics and predictive forecasts for material prices and cost overruns

Risk scoring across contracts, scope, and suppliers

Generative AI for project planning and design

Generative AI in construction enables a more disciplined approach to exploring design and planning alternatives under real-world construction constraints. Instead of narrowing options through successive manual iterations, teams can evaluate multiple constructable solutions that already reflect cost limits, regulatory requirements, and site conditions. Design decisions become more defensible earlier in the project lifecycle, reducing downstream revisions.

This planning model supports outcomes such as:

Constraint-driven design option generation

Real-time BIM-linked updates to cost and quantities

Optimized site layouts for constructability and logistics

AI in safety monitoring and construction risk assessment

AI changes safety oversight from periodic inspection to continuous control. Live site data from cameras, sensors, and wearables is evaluated against defined safety rules and historical incident patterns, allowing hazards to be identified before they escalate. Risk management becomes preventive, with interventions targeted to specific activities and conditions.

Organizations deploying AI-based safety monitoring report 22–25% reductions in workplace incidents, driven by continuous hazard detection and earlier intervention rather than post-incident review.

On active jobsites, AI and construction capability are expressed through:

Real-time detection of PPE gaps and restricted access

Predictive identification of high-risk activities and periods

Reduced exposure through automation of hazardous tasks

Predictive maintenance with AI

Predictive maintenance leads to reactive repair and fixed service intervals. Continuous monitoring establishes performance baselines for individual machines, while anomaly detection highlights early signs of degradation. Maintenance planning aligns with project schedules instead of interrupting them.

Operationally, this leads to:

Continuous monitoring of equipment health indicators

Early failure detection and planned maintenance windows

Extended asset lifespan and improved utilization rates

Benefits of using AI in construction

The adoption of AI in construction market addresses long-standing structural issues related to predictability, coordination, and risk control. AI enables earlier intervention based on continuously updated data from automated design generation models, schedules, equipment, and jobsites. When applied correctly, AI strengthens control across the entire construction lifecycle.

1. Higher productivity and execution consistency

AI productivity tracking systems reduce operational friction by automating time-consuming coordination and documentation tasks that traditionally absorb significant project effort. Routine activities such as document classification, daily reporting, progress tracking, and RFI handling can be automated from live project data, freeing teams to focus on coordination and decision-making.

Scheduling models continuously recalculate timelines as conditions change, accounting for weather, labor availability, and material delivery status rather than relying on static plans. On-site, robotics and semi-autonomous machinery perform repetitive physical tasks with consistent quality and precision, helping stabilize output even under labor constraints.

2. Stronger safety oversight and risk anticipation

Safety performance improves when hazards are identified early and monitored continuously rather than through periodic inspections. Computer vision systems analyze live video feeds to detect unsafe behavior, missing protective equipment, or unauthorized access in real time. Predictive models assess historical incident patterns alongside current site conditions to identify elevated risk zones or activities before incidents occur. Automation also reduces human exposure to hazardous environments.

3. More accurate cost control and financial predictability

AI strengthens cost management by replacing static estimates with continuously updated financial forecasts. Models trained on historical project data, current design attributes, and market indicators produce more reliable projections as scope or conditions change. Integration with BIM environments allows cost impacts to be recalculated automatically when designs evolve, reducing lag between planning decisions and financial insights. Predictive maintenance further protects budgets by identifying equipment issues before failures lead to downtime, schedule disruption, or emergency repairs.

4. Improved build quality and reduced rework

Quality control benefits from objective, data-driven verification rather than manual spot checks. Drones, sensors, and computer vision systems compare as-built conditions against design models to identify deviations early, when corrective action is still manageable. Automated inspections reduce reliance on subjective judgment and improve consistency across large or distributed sites. In design phases, generative models explore multiple constructable options within defined constraints, supporting better alignment between design intent, constructability, and cost expectations.

5. Better sustainability outcomes and lifecycle insight

AI contributes to sustainability by improving how materials, energy, and assets are planned and managed over time. Predictive models estimate material needs more accurately, reducing waste and excess procurement. During operation, AI-enabled smart building technologies optimize energy consumption by adjusting to occupancy patterns, environmental conditions, and equipment performance.

Over the full asset lifecycle, digital twin in construction with AI provide visibility into long-term maintenance needs and performance trends, supporting informed decisions that extend asset life and reduce environmental impact.

Keep reading to learn more how is AI used in construction based on real-time case studies.

Real-world success stories of AI construction from Acropolium

Scaling an enterprise construction management platform for data-driven project control

In the Acropolium enterprise construction management project, our team focused on scaling a complex, multi-tenant platform designed to support large construction portfolios with thousands of concurrent users. The work focused on stabilizing core workflows, restructuring data models, and introducing a modular architecture to support real-time reporting, advanced analytics, and future AI-driven capabilities. Particular attention was paid to data consistency across scheduling, cost control, and project tracking modules, using AI in construction to create a reliable operational backbone.

As a result of this approach, the platform achieved measurable gains in performance, scalability, and decision transparency across projects. Construction teams gained a consolidated view of progress, risks, and dependencies, while management benefited from faster access to structured, trustworthy data. This foundation enabled the incremental introduction of predictive insights and automation without disrupting ongoing operations, demonstrating that disciplined engineering and data design are prerequisites for sustainable AI adoption in construction environments.

Results achieved:

Improved system performance and stability under enterprise-scale workloads;

Increased visibility into project status, risks, and cross-project dependencies;

Reduced data fragmentation across planning, cost, and execution processes;

Established a scalable foundation for analytics and AI-driven project intelligence.

Building an AI-ready construction asset management platform

In this construction asset management cooperation, Acropolium delivered a centralized platform designed to track, manage, and analyze construction assets across their full lifecycle. Our work focused on structuring asset data to support real-time visibility, historical analysis, and future predictive use cases. The system unified information from equipment inventories, maintenance records, and operational logs into a single, coherent data model, eliminating manual reconciliation and fragmented reporting.

The resulting solution gave construction teams clear insight into asset availability, utilization patterns, and maintenance history, enabling more informed operational decisions. By establishing consistent data flows and reliable asset telemetry, the platform created a strong foundation for predictive maintenance and lifecycle optimization. This case demonstrates how disciplined data architecture and domain-specific engineering enable AI without disrupting existing construction operations.

Results achieved:

Improved visibility into asset utilization and availability across sites;

Reduced reliance on manual tracking and fragmented asset records;

Enabled data-driven maintenance planning and asset lifecycle control;

Prepared the platform for incremental adoption of AI-based asset analytics.

Key challenges of AI for construction and their mitigation strategies

While adoption of AI for construction continues to expand, sustained value depends on resolving a small number of structural constraints that repeatedly limit scale and reliability. Experience across real projects shows that most failures concentrate around the same core issues, regardless of company size or geography. Addressing these challenges early determines whether AI becomes part of day-to-day delivery or remains confined to pilots.

Data quality and continuity

AI relies on consistent, structured, and contextualized data drawn from design, planning, execution, and operations. In many construction environments, information remains fragmented across spreadsheets, PDFs, isolated BIM models, and subcontractor systems, which weakens model accuracy and confidence in outputs. The use of AI in construction may lead to inconsistent data definitions and missing historical records, further limiting the ability to train and validate models, especially on complex or unique projects. Mitigation requires establishing a shared data environment with clear ownership, standardized formats, and governance practices that ensure data is reliable, traceable, and continuously updated across the project lifecycle.

System integration and technical debt

Construction organizations typically operate with heterogeneous technology stacks. AI systems struggle when scheduling tools, cost systems, BIM platforms, and site telemetry operate in isolation or rely on manual data transfers. This technical debt slows feedback loops and prevents AI from delivering timely, actionable insight. Effective mitigation focuses on incremental integration through APIs and data pipelines, allowing AI to connect into existing workflows without forcing disruptive system replacement.

Workforce readiness and adoption

AI changes how planning, coordination, and control activities are performed, which directly affects established roles and responsibilities. Limited AI literacy, combined with uncertainty around accountability, often leads to cautious or inconsistent use of AI-generated insights. Adoption improves when teams understand how recommendations are produced, where human judgment remains mandatory, and how AI supports rather than displaces professional expertise. Mitigation depends on targeted training, clear operating guidelines, and change management that builds confidence through transparency and repeatable results.

Additional challenges to consider

Beyond these core issues, several secondary factors can influence AI outcomes in construction environments:

Financial constraints related to upfront investment in software, sensors, and infrastructure;

Governance and accountability concerns, including validation of AI outputs and responsibility for decisions;

Data security and privacy risks associated with increased digital connectivity across projects;

Connectivity and computing limitations on remote or large-scale jobsites;

Variability in regulatory and contractual frameworks that affect data sharing and automation.

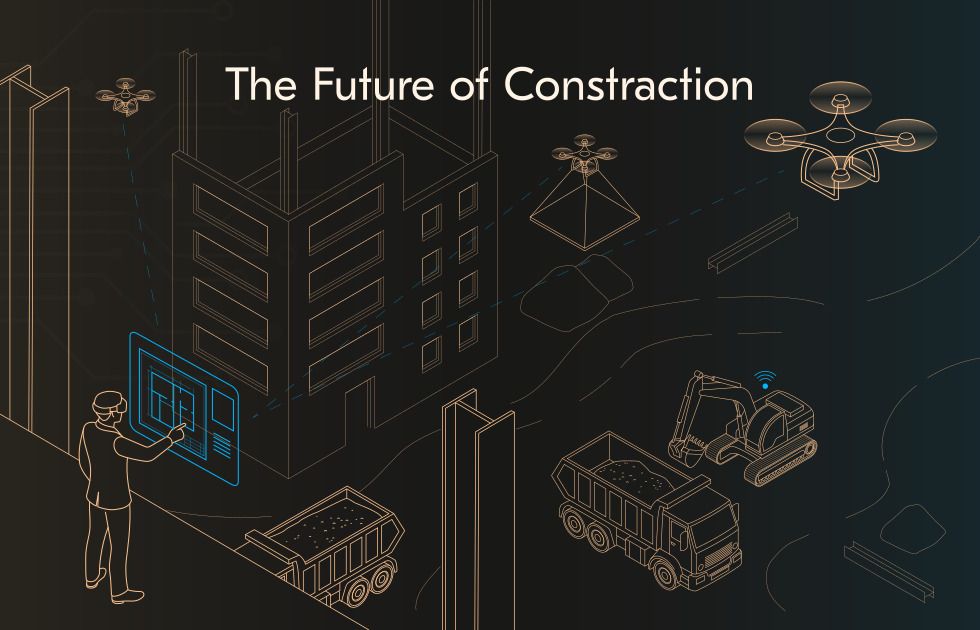

What is the future of AI in construction?

The future of Artificial Intelligence in construction market is defined by a gradual move from isolated use cases to coordinated, system-level adoption across planning, delivery, and asset operations. AI is becoming part of how construction organizations reason about uncertainty, rather than a standalone tool used for optimization in narrow areas. Market projections point to sustained growth, with estimates suggesting the Artificial Intelligence construction market could reach more than $20 billion by the early 2030s, driven by pressure to control risk, labour shortages, and rising project complexity.

Trend 1: Autonomous and robotic jobsites

Construction sites are beginning to incorporate robotics and automation at a scale that changes how work is organised. Autonomous and semi-autonomous machines already handle tasks such as earthmoving, material transport, and repetitive assembly in controlled environments. Over time, coordinated fleets of machines will execute tightly sequenced activities, particularly in hazardous or remote conditions where human exposure increases risk. Human involvement will remain central, but responsibilities will concentrate on supervision, sequencing, and intervention rather than continuous manual execution.

Trend 2: AI as an active decision system

AI systems are moving beyond passive analysis toward continuous decision support embedded in daily operations. Models increasingly monitor schedules, weather, logistics, and site conditions in real time, producing updated scenarios that guide corrective action before delays or cost overruns become visible through traditional reporting. Design and delivery workflows will continue to integrate AI-generated recommendations that reflect regulatory constraints, constructability limits, and resource allocation automation availability. Digital twins will extend beyond visualization, serving as operational control layers that reflect actual site and asset conditions throughout construction and into long-term operation.

Trend 3: Industrialized and data-driven construction delivery

AI adoption aligns closely with the broader move toward industrialized construction methods, including prefabrication and modular assembly. Construction and AI data-driven planning supports tighter coordination between design, manufacturing, logistics, and site execution. Procurement decisions will increasingly reflect predictive insight into commodity markets, supplier performance, and transport constraints, allowing better protection of cash flow and delivery schedule optimization. Environmental performance will also become more measurable, as AI models simulate material choices and operational energy use across the full lifecycle of an asset.

Trend 4: Workforce change and professional responsibility

AI adoption will reshape roles rather than remove the need for skilled professionals. Routine coordination, reporting, and compliance tasks will continue to decline in manual effort, while demand grows for expertise in system oversight, data interpretation, and cross-disciplinary coordination. New roles will focus on maintaining AI systems, validating outputs, and ensuring alignment with safety, contractual, and regulatory obligations.

Taken together, AI will not remove uncertainty from construction, but it will narrow the gap between what teams expect and what actually happens on site. Organizations that invest in data continuity, system integration, and responsible use of AI will gain a clearer view of risk, effort, and long-term asset performance. Those who delay will continue to manage complex projects with partial visibility and limited foresight.

If you are ready to assess where AI can deliver measurable value in your construction processes, contact us at Acropolium to discuss your goals and constraints. Let us support you with the next steps.

![AI in Retail: [Use Cases & Applications for 2025]](/img/articles/ai-in-retail-use-cases/img01.jpg)

![AI in Web Development in 2025: [Benefits, Trends & Use Cases]](/img/articles/ai-and-web-development-why-and-how-to-leverage-ai-for-digital-solutions/img01.jpg)

![Integrating Artificial Intelligence for Business Applications [A 2025 Guide]](/img/articles/artificial-intelligence-for-business-applications/img01.jpg)