Key Takeaways

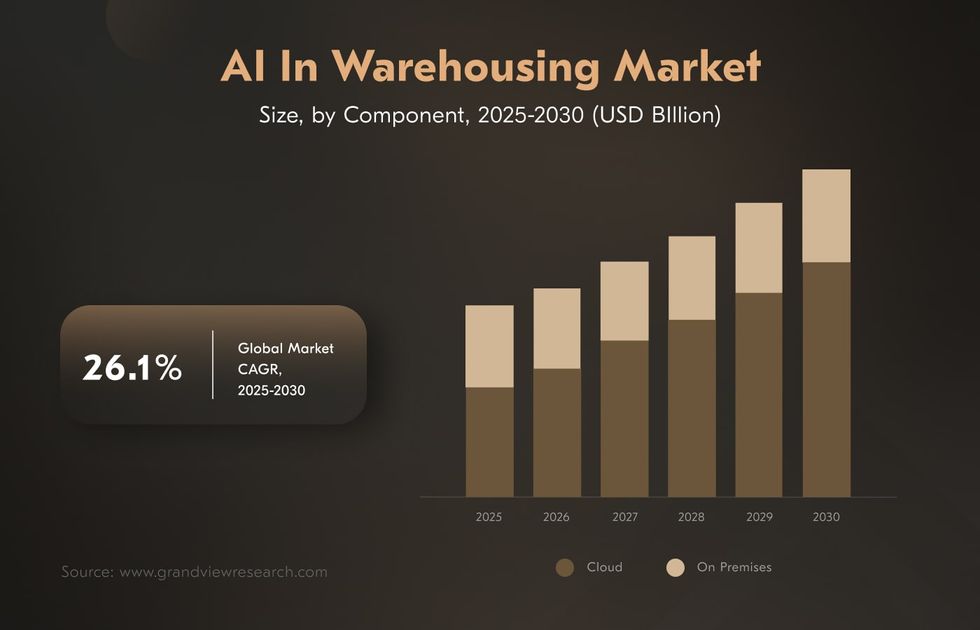

- The global AI warehouse market hit $11.22B in 2024 and is set out to grow by 26.1% annually through 2030.

- AI boosts warehouse efficiency through automation and smart scheduling, helping facilities operate around the clock while reducing downtime and reliance on manual work.

- Real-time insights from IoT and AI help leadership make informed decisions, improving resource allocation, labor planning, and risk management based on live warehouse data.

- AI warehouse solutions can help uncover 7-15% of underutilized capacity in operations by analyzing inefficiencies and performance gaps.

With the growing popularity of e-commerce and the demand for next- or even same-day delivery, both online retailers and traditional brick-and-mortar businesses are obliged to meet customer expectations while maintaining inventory accuracy and cost-efficiency.

To keep up, warehousing is undergoing a significant transformation, adopting AI in warehouse management. Artificial intelligence now stands at the core of this evolution, reimagining how warehouses function. From demand forecasting and stock replenishment to automation and anomaly detection, AI technologies make warehousing more adaptive, resilient, and scalable.

Through 12 years of delivering custom logistics and supply chain software, we’ve seen warehouses transform with AI, big data, and IoT. Today, we’ll focus on the main capabilities of artificial intelligence in warehouse management, sharing the latest data and most impressive real-world stories.

What is AI in Warehouse Management?

AI warehouse management implies the use of artificial intelligence technologies, such as machine learning, computer vision, and data analytics, to automate, optimize, and support decision-making across warehouse operations.

Its primary application is in the fulfillment stage, where it helps improve product placement, picking routes, robotic coordination, and identification of at-risk orders, all contributing to higher throughput and better labor utilization.

Beyond fulfillment, AI enhances strategic planning by improving demand forecasting, adjusting inventory levels in real-time, and helping warehouses respond more effectively to market fluctuations.

AI in warehousing is especially valuable for third-party logistics (3PL) providers, who manage multiple clients and must adapt quickly to varying product volumes, seasonal demand, and service-level agreements.

Therefore, the global AI in warehousing market was valued at $11.22 billion in 2024 and is expected to grow at 26.1% annually through 2030. Much of this growth comes from AI’s ability to uncover 7-15% of untapped capacity by analyzing resource availability, workload variability, and performance gaps across the network.

Benefits of AI in Warehouse Management

AI warehouse solutions offer more than standard automation. They enable real-time decision-making, apply predictive analytics, and support smarter resource allocation. This leads to greater inventory visibility, more efficient picking and packing processes, reduced labor costs, and faster, more reliable order fulfillment.

In fact, integrating AI in warehouse management can deliver substantial value for distributors, including procurement spend cuts of 5-15%. Now, let’s take a closer look at how else you can benefit from the technology.

Operational Efficiency

Intelligent systems automate routine tasks, coordinate workflows, and continuously adjust schedules based on real-time inputs. It helps lower downtime, minimizes errors, and keeps workflows smooth, even in the face of fluctuating demand. Warehouses can scale faster and handle greater volumes with the same or fewer resources.

Cost Reduction

While cutting procurement spend is already a win, the real savings often come from the way AI in warehouses optimizes inventory management. By applying machine learning and dynamic segmentation, AI forecasts demand more precisely, helping businesses avoid overstocking and stockouts.

This leads to leaner inventories, often reduced by 20 to 30%, while still meeting customer needs. Even simple AI-driven tools can unlock major cost efficiencies, all without overhauling your entire system.

Improved Accuracy

With AI and big data working in tandem, decision-making becomes both faster and more reliable. Data from across the supply chain — orders, supplier performance, transit times, returns — feeds into predictive models that spot inconsistencies or anomalies. It results in better order accuracy, fewer manual corrections, and a noticeable reduction in costly errors.

24/7 Autonomous Operations

Warehouse management systems equipped with autonomous technologies can operate around the clock, tracking goods in real time and maintaining visibility at every stage. Whether it’s monitoring inbound shipments or guiding robotic pickers, these tools ensure constant flow and responsiveness.

Such AI applications in warehouse management are especially useful in high-volume contexts or during peak seasons.

Enhanced Decision-Making

Equipped with IoT sensors gathering detailed data and AI analytics interpreting it, decision-makers get clearer insight into what’s really happening inside the warehouse. This includes workforce metrics, machine usage, storage patterns, and even environmental conditions.

For example, advanced analytics have helped major distributors cut operational costs by 15 to 20% by analyzing employee trends like performance, turnover, and satisfaction, suggesting ways to improve retention.

Real-World Cases & AI Applications in Warehouse Management

AI in warehousing has turned into a standard across modern supply chain transportation businesses, with many leading logistics and retail companies already integrating it into their core operations.

Now, it’s time to discover some of the most common AI use cases in warehouse management, each backed by real-world examples from companies that are setting the pace for innovation in this space.

Automated Picking and Sorting

Warehouses deploy AI-powered robotics and computer vision systems, often paired with IoT modules, to detect product identity, shape, orientation, and position. These systems dynamically adjust to handle thousands of SKUs, coordinating through real-time telemetry to guide arms or mobile bots in selecting and sorting items accurately and efficiently.

For example, Amazon operates a vast fleet of robotic arms and mobile units (such as Sparrow, Sequoia, Pegasus, and Proteus) that leverage AI in warehouses and embedded IoT data for picking, sorting, and transporting products across fulfillment centers.

These robots rely on vision models trained on massive image datasets and real-time sensor feedback to minimize mis‑picks and boost throughput. Amazon has confirmed deployment of over 750,000 such robots, illustrating widespread AI use in this domain.

Predictive Inventory Management

AI warehouse tools process historical sales, seasonality, supplier lead times, and real-time stock levels to forecast demand and trigger restocking or reallocations proactively. Such systems continuously re‑evaluate inventory placements and order suggestions based on shifting patterns.

One real-world illustration is Amazon’s predictive WMS, which integrates machine learning with IoT data across warehouse zones. That system anticipates product demand, flags anomalies, and helps minimize stockouts or overstocks, resulting in substantial cost reductions and service improvements.

Warehouse Layout Optimization

AI-driven digital twins simulate warehouse layouts, evaluating the placement of shelves, carton zones, and traffic routes. By testing countless configurations, AI in warehousing can recommend optimal slotting and aisle designs to reduce picker travel and ease congestion.

For instance, PSI’s AI-enhanced WMS creates a near real-time digital model of the warehouse ecosystem. During a pilot with a large fashion retailer, the system reduced route distances and improved productivity by dynamically updating layout decisions based on shifting demand patterns.

Autonomous Mobile Robots (AMRs)

Mobile robots paired with AI in warehousing systems, computer vision, and IoT sensing navigate warehouse floors autonomously. They detect obstacles, prioritize tasks based on urgency and inventory needs, and learn from environmental movement patterns for smoother routing.

Symbotic offers one such implementation: a fleet of fully autonomous robots orchestrated by AI-based software, handling mixed-SKU pallets, aisle traffic, and replenishment.

AI in Quality Control and Damage Detection

AI-based vision systems monitor goods as they arrive or depart, spotting damaged packages, mis-picks, or labeling errors in real time. Such AI warehouse solutions generate alerts or trigger corrective workflows immediately, reducing returns and maintaining order accuracy.

Broader logistics providers like Berkshire Grey deploy vision-integrated AI workflows for real-time item inspection, though the specific named firm example is less publicized.

Energy and Resource Optimization

Machine learning models ingest streaming IoT data from HVAC systems, lighting, conveyors, and other equipment to forecast optimal energy loads. At the same time, AI for warehouse management adjusts settings based on usage, time-of-day, or rate schedules, reducing energy waste, lowering expenses, and improving sustainability.

A real case comes from CEVA Logistics in partnership with BeeBryte, where refrigerated warehouse systems apply predictive AI adjustments to cooling cycles and equipment runtime. Resulting energy use shrank by over 30%, with annual savings in electricity consumption achieved solely through software optimization and sensor feedback.

AI-Enhanced Safety Monitoring

Integrating artificial intelligence in warehouse management allows companies to link modern systems with existing cameras and sensors to interpret safety behavior. That goes for monitoring PPE compliance, unsafe pathways or movements, equipment malfunctions, and temperature or vibration anomalies.

The system generates predictive alerts before accidents or operational issues escalate.

A practical example can be seen in providers like Arvist AI and Chooch AI deploying vision‑based systems to monitor warehouse safety and operations. These solutions detect behavior deviations or hazard zones, alerting teams before a mishap occurs, demonstrating the proactive risk mitigation possible with AI-enhanced safety monitoring.

Using AI for Warehouse Management Challenges

Even with increased digitalization, many warehouses still struggle with core operational inefficiencies. Outdated ERP systems, disconnected processes, and manual workarounds leave little room for agility. AI offers a more adaptive, data-driven alternative, which is capable of solving long-standing issues without disrupting entire tech stacks.

Especially when supported by experienced offshore development partners, the integration of AI in warehouses can be scaled cost-effectively and tailored to complement existing workflows. Here’s how AI addresses some of the most persistent challenges in warehouse operations.

Inventory Inaccuracy

Traditional inventory systems often rely on batch updates and human input, both of which are prone to errors. When warehouses operate on legacy ERPs with limited real-time data capabilities, these inaccuracies compound over time, leading to costly stock discrepancies and fulfillment issues.

By integrating AI in warehousing with IoT sensors and computer vision, stock levels can be updated continuously and verified automatically. If items are misplaced, overcounted, or misclassified, AI-driven systems can detect inconsistencies instantly, ensuring that records match physical inventory far more reliably.

Labor Shortages and High Turnover

Finding and retaining skilled warehouse staff has become increasingly difficult, notably in high-volume or seasonal changes. High turnover disrupts workflows, increases training costs, and puts additional pressure on remaining teams. AI doesn’t replace human labor outright, but it does reduce reliance on manual intervention for repetitive, time-consuming tasks.

With the help of autonomous mobile robots, smart scheduling algorithms, and predictive maintenance AI warehouse tools, businesses can redistribute workloads, maintain performance during staffing gaps, and onboard new hires more smoothly.

Offshore development teams also play a role here by helping tailor these AI tools to fit the needs of specific operations without the cost burden of full in-house teams.

Inefficient Order Picking

Picking remains one of the most labor-intensive and error-prone tasks in warehouse logistics. In many facilities, workers follow static pick lists generated by legacy systems that don’t account for real-time inventory positions or warehouse traffic.

Artificial intelligence in warehouses optimizes this process by dynamically mapping out the most efficient picking paths, taking into account stock locations, order volume, and even picker fatigue. When combined with computer vision or voice-assisted systems, the result is a faster, more accurate, and less physically taxing picking process.

Poor Demand Forecasting

Forecasting demand manually or relying on obsolete software reports often leads to reactive decisions, either overstocking items that won’t sell or running out of high-demand SKUs at the wrong time.

AI in warehouse management eliminates much of the guesswork by analyzing real-time sales data, market trends, seasonality, and even weather patterns to predict shifts in demand. This allows for smarter procurement planning and inventory distribution, helping warehouses avoid bottlenecks and lost sales.

Also, offshore AI development or outstaffed dedicated teams can fine-tune these forecasting models to accommodate specific product categories, regions, or logistics constraints, making the solution even more effective.

Why Choose Acropolium: Case Studies

Celebrated by TechBehemoths for our broad industry expertise in bespoke software development, our dedicated teams put clients at the heart of every engagement, keeping their data secure, compliant, and ready to drive real business outcomes.

Using cutting‑edge tools and a cloud‑native, flexible infrastructure, we craft solutions that tackle today’s supply chain and warehousing transportation challenges head‑on, turning disparate operational data into timely, actionable intelligence.

Following ISO‑certified practices, we have developed and modernized over 23 warehouse and transport management systems while helping our clients reduce development costs. And below is one of the cases that speaks for itself:

WMS Modernization with Big Data

A mid‑sized logistics provider wanted to replace their legacy system with a predictive, data‑driven platform that seamlessly unifies ERP, IoT sensor streams, and sales inputs into a continuous live pipeline.

Solution

- We designed containerized microservices to scale without downtime, replacing legacy modules with a centralized data lake.

- Implemented live dashboard and forecasting updates.

- Machine learning models now forecast stock swings and optimize replenishment, while advanced dashboards let planners track KPIs in minutes instead of hours.

- Automated ETL workflows eliminate manual reconciliation, and granular access controls with full event logging ensure audit readiness.

- Comprehensive onboarding and documentation smoothed the transition for both planners and data engineers.

Results

- 30% increase in forecast accuracy

- 20% reduction in inventory holding expenses

- 25% gain in operational efficiency

Final Thoughts

AI in warehouse management steadily redefines what’s possible in warehouse operations by layering intelligence into processes that have long relied on reactive workflows. As more companies shift to predictive models and connected systems, the benefits compound: lower operational overhead, faster fulfillment, and the ability to respond in real time to both customer demand and supply chain disruption.

Whether it’s optimizing layouts with digital twins, streamlining order picking with robotics, or forecasting more accurately with machine learning, the long-term gains are already clear across the industry.

For businesses ready to modernize their logistics systems without the risk of expensive overhauls, Acropolium offers a flexible, subscription-based development model. With deep expertise in AI, IoT, and cloud-native architecture, our teams work as long-term technology partners, helping clients gradually build intelligent, scalable products that fit their exact operational needs.

![Fleet Fuel Management System [Complete Guide]](/img/articles/build-a-fuel-management-system/img01.jpg)

![Blockchain for Supply Chain Management: [Benefits & Use Cases]](/img/articles/why-and-how-to-employ-blockchain-in-supply-chain-management-tips-and-success-stories/img01.jpg)

![ᐉ Warehouse Management Systems Development [2025 Guide]](/img/articles/warehouse-management-systems/img01.jpg)

![Best Trucking Software in 2025: [Custom or Off-The-Shelf]](/img/articles/best-trucking-software-to-consider-custom-vs-off-the-shelf/img01.jpg)