Key Takeaways

- WMS system is a platform that helps organizations effectively handle warehouse operations, including inventory, order fulfillment, and logistics processes.

- The main types of warehouse management systems include standalone, cloud-based, supply chain, and integrated ERP modules.

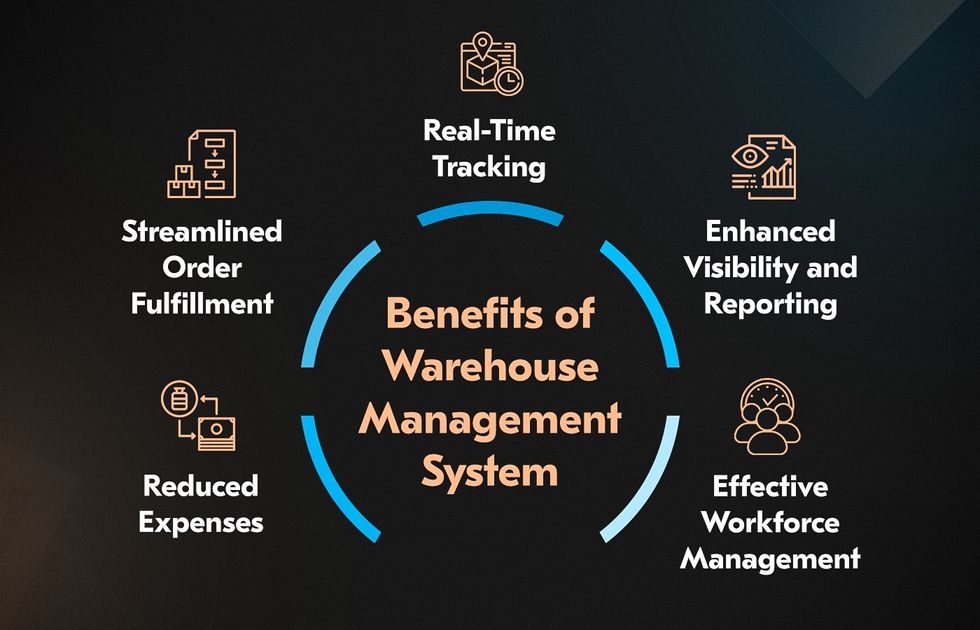

- Warehouse management software allows real-time tracking, improves data visibility, speeds up order fulfillment, effectively manages workforce, and reduces operational costs.

According to the GlobeNewswire survey, to drive success in 2023, you should focus on customer satisfaction (34%), technology automation (31%), sustainability (31%), workforce efficiency (31%), and fast delivery (30%). And all this can be done with the help of a suitable Warehouse Management System (WMS).

What is WMS system, and which type of WMS will suit your needs? What benefits can you expect? What big brands implement such solutions? Acropolium, an experienced logistics software provider, will answer all these questions. Also, you will learn how we’ve modernized the TMS, digitized the international trade platform, and connected 1000 IoT to the fleet tracking app.

What Is Warehousing Management System

Let’s start with a warehouse management system definition.

WMS solution serves as a central hub where managers can monitor inventory levels, track the movement of goods, and oversee order fulfillment processes. Warehousing management software captures real-time data from barcode scanning or RFID technology to maintain accurate inventory records and efficient product tracking.

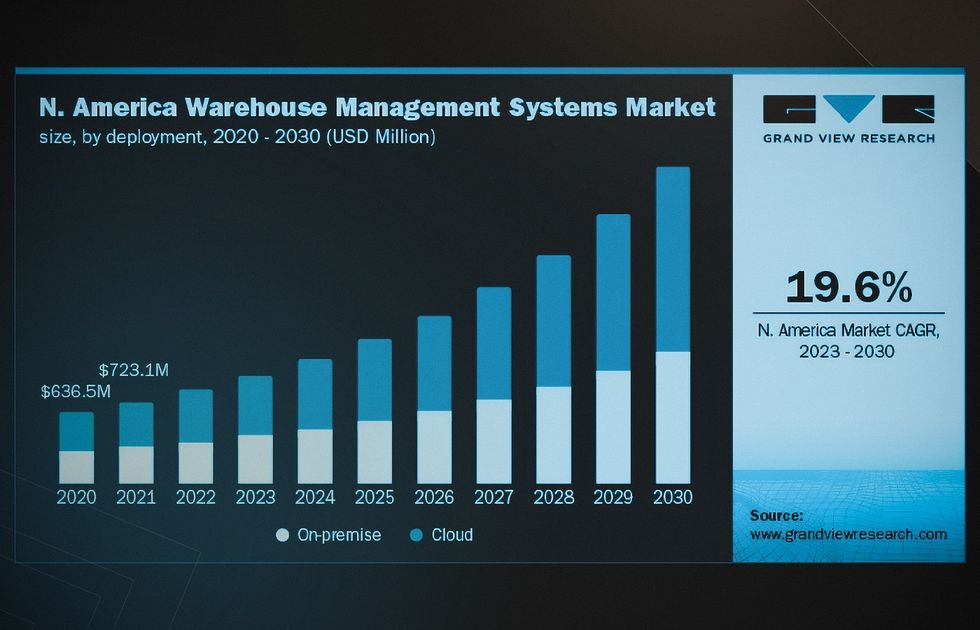

From 2023 to 2030, the global WMS market is projected to grow at a CAGR of 19.0%. This growth is caused by the increasing demand for WMS and decreasing logistics challenges created by fluctuating product markets and shipping schedules.

Four Types of Warehouse Management Software Systems

There are four warehouse management system examples that businesses use to improve operational efficiency and optimize warehouse operations.

Standalone WMS

A standalone WMS platform is a software solution that operates independently. It is typically customized to align with specific warehouse processes and requirements.

This WMS software offers high control and customization. It enables companies to manage inventory, track shipments, optimize warehouse operations, and generate reports. Most standalone WMS software companies require one-time purchase and installation charges.

It is ideal for small to mid-sized businesses with limited IT resources or complex integration requirements. It provides the basic functions of WMS but doesn’t require much integration efforts. It typically offers a more cost-effective option compared to integrated systems.

Cloud-Based WMS

A cloud-based warehouse management system is hosted on the vendor’s servers and accessed via the Internet. This eliminates the need to handle the infrastructure and IT resources.

Users can benefit from automatic updates, access to the latest WMS features and security patches without manual installations. Providers implement robust security measures, including encryption, access controls, and regular backups.

However, cloud-based warehouse software systems may offer less flexibility for customization compared to standalone systems.

Cloud-based WMS in logistics is perfect for retailers with multiple warehouses or remote teams, offering flexibility and working well with growing businesses. Cloud warehouse management systems are usually subscription-based.

Integrated ERP WMS

This warehousing software is tightly integrated with your enterprise platforms, such as ERP or TMS. It facilitates seamless big data sharing and synchronization between the systems. It ensures an accurate and up-to-date information transfer across the supply chain. ERP WMS systems streamline workflows and support efficient coordination between departments and functions.

But integration with existing systems can be complex and time-consuming, requiring careful planning and testing. Also, the initial WMS software price can be higher compared to standalone or cloud-based solutions.

An integrated warehouse system is well-suited for businesses that have multiple departments or complex supply chains, and already have ERP, CRM, or inventory management systems.

Supply Chain WMS

A supply chain WMS app manages and optimizes operations within a large distribution network. It provides end-to-end visibility and control over inventory, storage, and movement of goods. Also, the supply chain management app facilitates seamless collaboration and data sharing among stakeholders, suppliers, manufacturers, distributors, and retailers.

Implementing and maintaining such warehouse management solutions can involve significant upfront and ongoing costs, including software licenses, hardware, infrastructure, and training.

The supply chain WMS warehouse management system is suitable for businesses of all sizes that manage complex inventory and warehousing operations. It is particularly beneficial for companies operating in retail, e-commerce, manufacturing, distribution, and logistics sectors.

Warehouse Management System Features

Essential warehouse management system features include:

- Barcode Scanning.

- RFID Technology.

- Integration with IoT devices.

- Data synchronization.

- Real-time reporting and dashboards.

Barcode Scanning

Affix barcodes on items, pallets, or bins, allowing warehouse personnel to scan them using handheld devices or scanners. It enables real-time updates on inventory levels and location tracking, and facilitates efficient order fulfillment.

RFID Technology

Attach Radio Frequency Identification (RFID) tags to products or pallets to capture the information wirelessly. This technology offers faster hands-free scanning and the ability to read multiple tags simultaneously.

Integration with IoT devices

Gather data from sensors and equipment within the warehouse. IoT devices can monitor temperature, humidity, motion, or other environmental conditions, ensuring optimal storage and handling of goods.

Data synchronization

Enable real-time updates across the supply chain by synchronizing data with ERP or TMS. Improve inventory visibility, order status tracking, and collaborative decision-making.

Real-time reporting and dashboards

Monitor inventory levels, order statuses, pick rates, and other relevant metrics in real-time. With comprehensive visibility into warehouse operations, you can identify bottlenecks, make informed decisions, and optimize processes.

Benefits of Warehouse Management System

What is WMS software in terms of benefits for your business? Let’s explore the most significant advantages.

Enhanced Visibility and Reporting

Warehouse management tools provide real-time and comprehensive visibility into storage operations. It allows managers to monitor inventory levels, track order status, and analyze performance metrics. The system generates detailed reports on KPIs, such as order fulfillment rates, inventory accuracy, and labor productivity.

With logistics software modernization, businesses can respond quickly to changes in demand or supply. Additionally, generating customizable reports allows you to analyze trends, forecast demand, and identify potential bottlenecks or inefficiencies in the warehouse.

Real-Time Tracking

With barcode scanning, RFID, or IoT devices, warehouse software programs capture real-time data and update the system instantaneously.

Real-time tracking allows you to optimize inventory placement, improve order accuracy, and reduce the risk of stockout or overstock situations. Also, you can identify bottlenecks, optimize routes, and proactively address potential issues.

Streamlined Order Fulfillment

By utilizing WMS software development, businesses improve order accuracy. The system helps eliminate manual errors in order processing, ensuring that the right products are picked, packed, and shipped to customers.

With barcode scanning and automated order validation, companies can minimize order discrepancies and reduce returns. Also, you will improve customer satisfaction as the correct products will be delivered on time.

Effective Workforce Management

Warehouse software development services provide tools that help assign appropriate workloads, prioritize tasks, and optimize picking routes. With accurate and timely employee performance tracking, managers identify areas of improvement and implement metrics-based incentives.

Create optimized schedules and ensure the right number of staff is available to handle peak periods or unexpected surges in demand. Proper logistics management will improve labor efficiency, reduce idle time, and enhance productivity.

Reduced Expenses

Warehouse management solution companies can optimize your stock levels, avoiding overstocking and stockouts. Efficient space utilization eliminates the need for additional storage facilities which reduces associated expenses. At the same time, scanning technology ensures accurate picking, packing, and shipping. It will minimize costly errors and returns.

With the streamlined processes and task management, you can reduce unnecessary labor expenses. Additionally, proactive equipment maintenance and tracking can minimize breakdowns and downtime, leading to budget savings on repairs and replacements.

Real-World Examples of Companies That Have Successfully implemented WMS

Let’s discover what big companies already felt the benefits of WMS:

- Amazon’s WMS handles a vast inventory across multiple distribution centers, ensuring efficient product flow and fast delivery options.

- Walmart facilitates just-in-time delivery practices, shipping products precisely when needed to minimize inventory holding costs.

- FedEx is known for its focus on shipment visibility. This includes tracking updates, estimated delivery times, and proof of delivery information.

- DHL’s WMS integrates with conveyor systems and automated guided vehicles to enable efficient and automated movement of goods within the warehouse. It leads to improved productivity and reduced manual handling.

- UPS’s WMS is designed to handle different product types, packaging requirements, and order fulfillment processes, providing flexibility to adapt to specific business needs.

Why Choose Acropolium?

Acropolium is a reliable award-winning agency with 20+ years of experience and a proven track of projects for logistics, transportation, and supply chain companies. We provide custom software solutions using the latest technologies and industry best practices, including IoT, AI/ML, GIS, chatbot, etc.

Our dedicated team uses bespoke software, compliant with GDPR and ISO management standards. We focus on strong security measures — from encryption and HTTP protocols to serverless frameworks.

Acropolium Case Studies

Acropolium has successfully executed numerous cases in the logistics and transportation industry. Let’s overview some case studies.

International Trade Digitalization & Paper Work Automation

For an international trade provider, Acropolium created a SaaS solution from scratch, which effectively automated the work process. Our team simplified the process of verifying country-specific shipping requirements and document creation.

Besides, we fully digitized document management. All of this led the company to increase annual revenue by 65%, attract 37% more new customers, and reduce personnel costs by 60%.

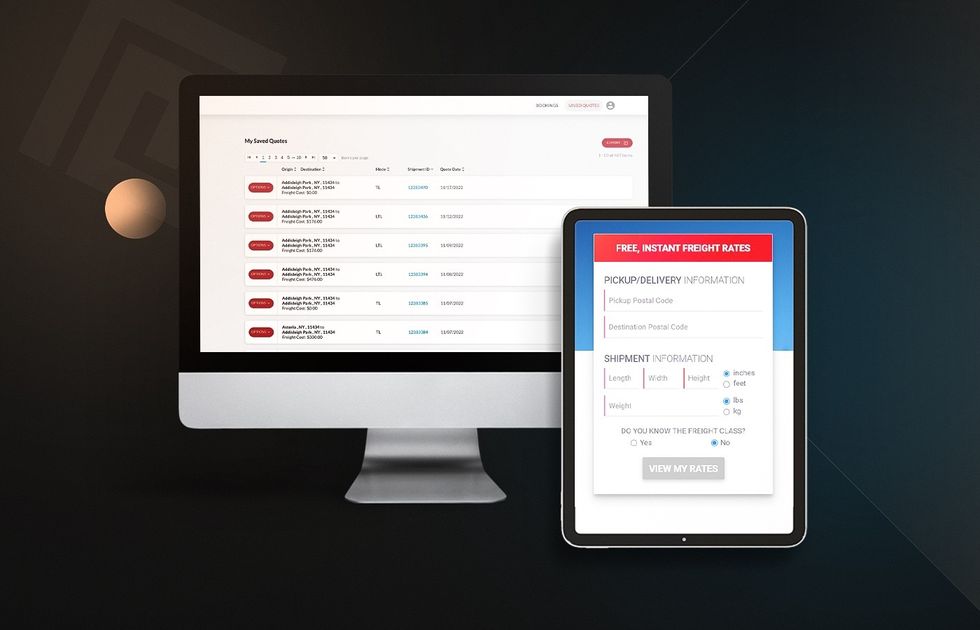

Transportation Management System (TMS) Modernization

A freight forwarder approached us to modernize the TMS platform and improve customer service. The company requested a fast and stable solution serving over 1 billion shippers.

In just three months, we provided a solution with the required performance. Now, the customer saves about $10,000 a year on hosting and $5,000 a month thanks to switching to an in-house zip code database.

IoT-Based GPS Fleet Tracking App Development

For another client, we’ve developed an IoT-based solution which allows them to track their car fleet in real time. We’ve added data visualization and remote command processing. The software we created is based on AWS and can display up to 1000 trucks on a map.

Also, the new system enables this company to generate reports within 15-29 seconds, instead of 4 days, as before.

Final Thoughts

Warehouse management system software improves real-time tracking, visibility, operational efficiency, and customer satisfaction. Whatever your company needs, you will surely find a solution that optimizes your processes and increases your competitive advantage.

If you’re looking for an experienced IT outsourcing partner, Acropolium offers a subscription-based service. It covers all common needs of secure logistics app development projects, including quality low-code solutions at a monthly fee. Contact our team to leverage the power of WMS.

![The Best Route Optimization Software to Employ in [2024]](/img/articles/route-optimization-software/img01.jpg)

![Logistics Management System [2024 Guide]: Use Cases Included](/img/articles/logistics-management-system/img01.jpg)