Key Takeaways

68% of executives believe advanced digital tools, including generative AI supply chain tools, are instrumental in improving visibility and collaboration.

93% of CEOs expect GenAI to deliver significant business value within the next 12 months.

74% of top organizations report a positive impact from generative AI investments in their customer service operations.

65% of supply chain officers expect AI to optimize or automate 26% to 50% of procurement tasks within three years.

According to Economist Impact, 55% of executives expect major disruptions in their supply chains, which highlights the need for innovative and forward-thinking approaches to operations. And this is where generative AI in supply chain and logistics comes into play.

The advantages of AI in terms of competition, cost, and strategy are just too big to ignore. In fact, 68% of executives agree that advanced digital solutions are key to dealing with potential challenges, improving visibility, and fostering better collaboration across the chain.

Simultaneously, 93% of CEOs believe that adopting GenAI could bring significant value in the next 12 months. With 10 years of crafting logistics software and breathing AI & ML into our clients’ workflows, Acropolium knows how transformative it can be.

Today, we want to show you how generative AI improves supply chain management with the most impactful real-world applications and success cases. Dive in to learn about its benefits, challenges, and solutions!

What is Generative AI in Supply Chains?

Unlike traditional AI applications, which are limited to specific tasks, Generative AI (GenAI) can create entirely new content, from texts and images to models. Thanks to its self-learning abilities, generative AI in logistics and supply chains can cover a lot of fundamental tasks.

Powered by deep learning and trained on tons of data, GenAI can spot patterns and structures to generate content that’s both realistic and relevant. It can quickly analyze different types of data, both structured and unstructured, model and optimize strategies using real-time data.

It can even generate automated content like reports and visualizations while sifting through large amounts of complex data to extract key insights and provide instant answers to questions. These capabilities make GenAI a game-changing trend for supply chain processes.

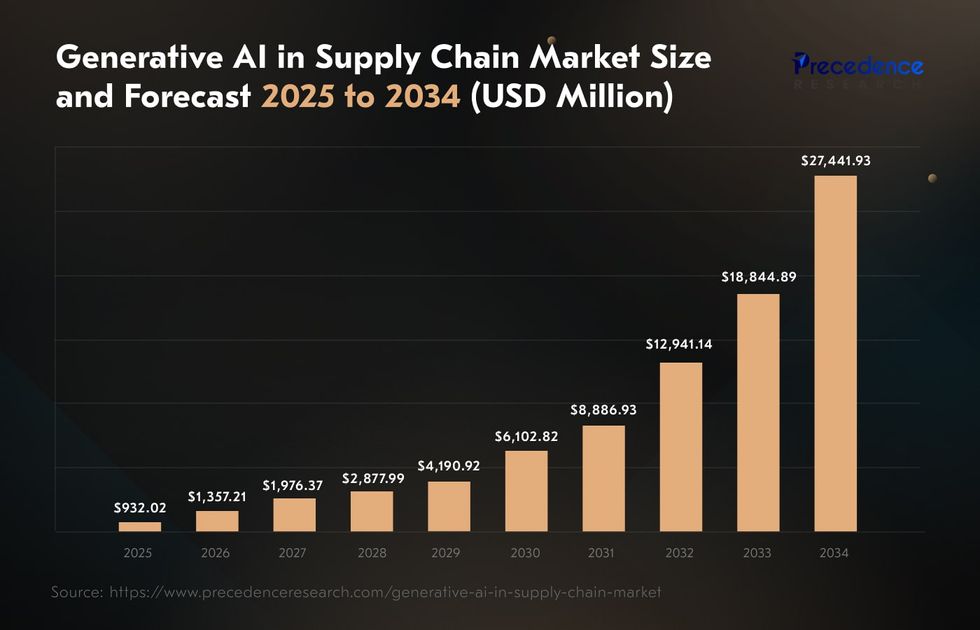

It’s already being used in the sector to make operations more agile, productive, and resilient. Thus, the global market for generative AI in supply chains was valued at $932.02 million in 2025 and is projected to hit about $27,441.93 million by 2034.

Benefits of Generative AI in Supply Chain and Logistics

The adoption of generative AI for logistics operations grows each day. 74% of top organizations say their investments in generative AI are having a positive impact on their customer service centers. Now, let’s take a look at some of the most valuable scenarios that GenAI can make a reality.

Better Demand Forecasting

With supply chain generative AI analytics, business strategies get a big boost from the predictive perspective. It pulls insights from unstructured data like customer behavior and product details to help forecast demand more accurately.

Analyzing different scenarios and patterns, it helps forecast shifts in demand, so you can adjust operations before stockouts or overstocking happen. This way, companies always have the right products available when needed.

Improved Risk Management

GenAI helps companies manage supply chain risks by analyzing past data and running predictive models to spot potential disruptions — like supply shortages or shipping delays — before they take place.

Such insights allow businesses to take action early to reduce the impact of unforeseen events, making decisions that keep operations running smoothly and avoid major setbacks.

Optimized & Automated Inventories

Managing inventory gets easier with GenAI. It helps companies optimize stock levels in real-time, automatically replenishing items as needed and adjusting inventory based on demand.

That’s why 65% of supply chain officers surveyed expect it to optimize or automate between 26% and 50% of their current procurement within the next three years. By predicting demand more accurately, GenAI reduces excess stock, cuts down on storage costs, and prevents running out of key products.

Reduced Transportation Costs

Transportation can take up a large chunk of supply chain costs, having jumped in the first half of 2024 due to huge disruptions in key shipping routes and rising operational expenses. However, GenAI helps trim these expenses by optimizing delivery routes and predicting demand.

Generative AI in transportation and logistics analyzes shipping patterns, traffic, and weather to recommend the most efficient routes, cutting down on delays and fuel use. This not only saves money but also makes deliveries more sustainable by reducing underloaded trucks.

Scalability & Efficiency

One of the biggest advantages of GenAI lies in its ability to scale along a growing business. As companies expand or deal with more data, generative AI in supply chains can handle the increased load with ease. It automates tasks that used to take up a lot of time, freeing up resources and improving overall efficiency.

With GenAI, businesses can manage complex operations without missing a beat, ensuring smoother expansion while maintaining high performance.

Generative AI Use Cases in Supply Chains & Logistics

Companies around the world are already tapping into gen-AI’s capabilities, and getting ahead of the curve is becoming essential for staying competitive. Many are investing in it, recognizing its growing role, with 78% of executives being supportive of AI-related investments.

Let’s see the modern generative AI applications in supply chains exemplified by the world’s leaders.

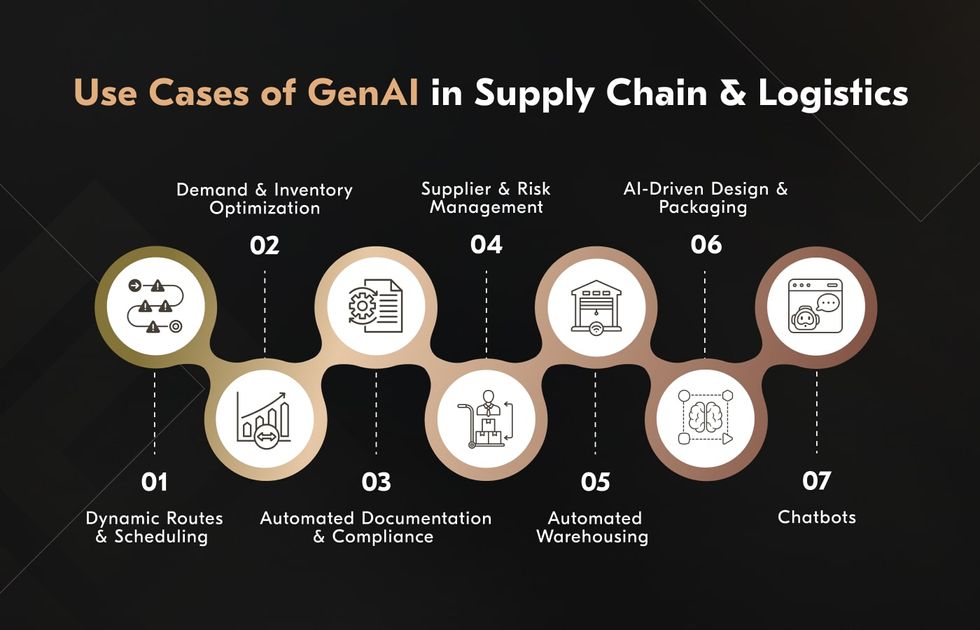

Dynamic Routes & Scheduling

Last-mile delivery is one of the most costly and complex parts of logistics, making up to 50% of total delivery costs. Integrated within a transportation management system, GenAI offers a smart solution by continuously optimizing delivery routes in real-time.

Generative AI in logistics collects and works with data on traffic, weather, and delivery priorities, dynamically adjusting routes and schedules for maximized efficiency.

That’s how DHL is using GenAI to reroute deliveries in response to real-time events while lowering fuel consumption and CO2 emissions. Faster, more reliable, and sustainable deliveries also improve customer satisfaction.

Demand & Inventory Optimization

Supply chain generative AI helps logistics companies stay ahead of shifting demand by optimizing both delivery routes and inventory distribution. As traffic conditions change throughout the day, GenAI dynamically recalculates fleet routes to avoid delays. At the same time, it monitors live demand signals across multiple warehouses, automatically redistributing inventory when one facility is overloaded.

Retail giants like Walmart leverage AI-driven inventory management to balance stock levels across fulfillment centers, ensuring faster deliveries and reducing bottlenecks. By predicting demand surges and optimizing supply distribution, the company improves efficiency, cuts costs, and enhances customer satisfaction.

Automated Documentation & Compliance

GenAI transforms trade compliance by sorting documentation and optimizing global trade operations. It evaluates current trade data — volumes, costs, and timelines — to map existing trade flows and identifies potential bottlenecks.

At the same time, generative AI applications in logistics integrate regulatory, tariff, and logistical data from multiple sources, creating a comprehensive view of global trade constraints.

For example, Maersk, a global shipping leader, has leveraged AI-driven automation to optimize customs documentation and trade compliance. The company analyzes regulatory requirements across different countries, which significantly reduces processing times and minimizes human errors in its global shipping operations.

Supplier & Risk Management

Businesses often employ GenAI as a built-in risk analyst for logistics, constantly scanning for problems. Whether it’s a supplier going bankrupt or a major weather event disrupting shipments, generative AI in supply chains runs simulations to predict potential issues and automatically suggests solutions.

Take Siemens, for example. During the COVID-19 pandemic, the company used AI-driven risk analysis to track supplier stability and spot potential shortages. By analyzing financial reports, global events, and logistics data, Siemens was able to quickly adjust sourcing strategies and keep operations running smoothly.

Automated Warehousing

Automation features of GenAI reimagine modern warehousing by keeping robots and workers in perfect sync. Instead of following fixed routes, AI dynamically fix picking paths based on worker positions, robot movements, and order priorities.

Supply chain generative AI even customizes packing strategies on the fly, ensuring maximum container space usage while keeping items secure. This smart coordination speeds up fulfillment, reduces errors, and makes warehouses more efficient at handling high order volumes.

The real test of warehouse management came during the holiday rush at Amazon. The company delivered 35% more packages on time compared to the previous year.

AI-Driven Design & Packaging

Generative AI streamlines product and packaging design by quickly generating and evaluating hundreds of variations based on specific goals. Companies can set parameters like durability, aesthetics, or sustainability.

Using predefined criteria — such as cost-efficiency or visual appeal — AI can rapidly iterate, evaluate, and refine ideas that would take weeks or months with traditional methods.

A notable example is Coca-Cola, which used GenAI to redesign its bottle, reducing plastic use while maintaining structural integrity and visual appeal. This approach is part of Coca-Cola’s broader initiative to lower its manufacturing footprint and promote sustainable packaging

Customer Experience & Chatbots

The use of AI chatbots allows businesses to operate 24/7, ensuring that customers receive immediate assistance at any time of day or night, regardless of location. This significantly reduces wait times and gives managers to focus on activities requiring a personal touch.

From tracking shipments to resolving logistics issues, generative AI supply chain bots help customers access critical information quickly, improving satisfaction and operational efficiency.

UPS has leveraged AI and chatbots in its My Choice platform, which allows customers to track packages, manage deliveries, and receive live updates. The system is designed to smoothen communication and help customers make more informed decisions regarding shipment times, locations, and preferences.

Generative AI in Supply Chain Management: Challenges & Tips

Adopting AI-driven solutions comes with challenges that businesses must assess carefully — especially with 84% of digital transformation efforts are at risk of failure. Still, 30% of companies successfully navigate the process by taking the right approach.

From protecting sensitive data to ensuring fair decision-making and integrating new technology into current systems, a good strategy will help you make the most of generative AI in supply chains.

Data Privacy and Security

Supply chain management software processes vast amounts of sensitive data, from supplier contracts to customer information. Generative AI requires continuous access to this data to function effectively. Still, improper handling can lead to security breaches or compliance issues.

To mitigate risks, companies should implement strong encryption, restrict data access, and ensure AI systems comply with global data regulations like GDPR and CCPA.

AI Biases and Decision-Making Risks

Supply chain generative AI models learn from historical data, which means they can inherit biases that lead to unfair or inaccurate decisions. It can be favoring certain suppliers or misjudging demand patterns.

Businesses must regularly audit AI outputs, retrain models with diverse datasets, and introduce human oversight to ensure fair and reliable decision-making.

Integration with Legacy Infrastructures

Many supply chain operations still rely on legacy software and traditional logistics networks that weren’t built for AI-driven automation. Integrating GenAI with these systems can be complex, requiring API connections, cloud migration, or custom development.

To ease the transition, companies should start with pilot projects, invest in scalable AI solutions, and ensure compatibility with existing infrastructure before full-scale implementation.

Why Сhoose Acropolium?

Named one of the best AI software development companies, Acropolium helps businesses navigate AI adoption with confidence.

Our expertise spans GDPR-compliant software, ISO-certified processes, and serverless solutions, ensuring data security, compliance, and scalability. Whether integrating AI into legacy systems or optimizing logistics workflows, our dedicated teams provide the technical foundation needed for a smooth transition.

Acropolium Case Studies

We ourselves saw how game-changing generative AI in supply chain operations can be. Here are some of our partners’ success stories that serve as living proof!

AI & SaaS-based Route Planning Tool

As our client’s logistics and fleet operations expanded, inefficiencies grew due to limited software capabilities. To stay competitive, the client partnered with Acropolium to develop a SaaS route optimization platform that would enhance fleet performance and streamline operations.

Solution

We conducted a thorough discovery phase to analyze logistics challenges and client objectives. Based on these insights, we developed a scalable SaaS route optimization platform with the following features:

Automated route planning powered by machine learning for continuous optimization.

Live data integration with Google Maps API and OpenStreetMap for adaptive routing.

Cloud scalability with AWS infrastructure to efficiently manage growing data loads.

Centralized fleet tracking for real-time vehicle monitoring and performance insights.

Comprehensive analytics for data-driven decision-making and operational improvements.

Results

15% profit increase due to reduced fuel costs.

25% growth in customer retention.

25% improvement in logistics efficiency with enhanced scheduling and AI-based real-time tracking.

Supply Chain Data Analytics Software

A leading logistics company needed to optimize operations and meet diverse customer demands, including expedited shipping and just-in-time delivery. They aimed to leverage data analytics and generative AI in supply chain activities to enhance efficiency while optimizing inventory.

Solution

We developed a robust supply chain analytics platform with the following benefits:

Predictive analytics and machine learning for improved demand forecasting and inventory accuracy.

Advanced big data integration to consolidate information from various sources into a centralized repository.

Intuitive dashboards and reports for real-time supply chain performance monitoring and decision-making.

Strong data security measures, including encryption protocols and access controls, ensure GDPR compliance.

Results

System downtime reduced by 20%.

Operational efficiency improved by 27%.

Inventory costs lowered by 15% through optimized management.

Customer retention increased by 22% due to personalized engagement and enhanced service quality.

Final Thoughts

Generative AI in supply chains and logistics is breathing a new technological spirit into the industry, making it more agile and resilient. Yet, integrating AI-driven solutions requires the right expertise to ensure smooth adoption and measurable results.

Acropolium helps businesses leverage AI in logistics with a transparent, subscription-based model. Our team builds scalable, secure, and tailored solutions —be it route optimization, demand forecasting, or automated inventory management.

With our experience in AI-driven logistics software, we ensure seamless integration and long-term efficiency. Let’s turn AI potential into real-world impact!

![Supply Chain Analytics Software [Key Features & Use Cases]](/img/articles/supply-chain-analytics-software/img01.jpg)

![Warehouse Automation Systems [8 Benefits for Your Business]](/img/articles/warehouse-automation-systems/img01.jpeg)

![6 Use Cases of AI in Transportation and Logistics: [2025 Edition]](/img/articles/ai-in-transportation/img01.jpg)

![ᐉ Logistics Customer Portal Development: [2025 Guide]](/img/articles/logistics-customer-portal-development/img01.jpg)

![AI Route Planning in 2025: [Use Cases & Benefits]](/img/articles/ai-route-planning/img01.jpg)