Key Takeaways

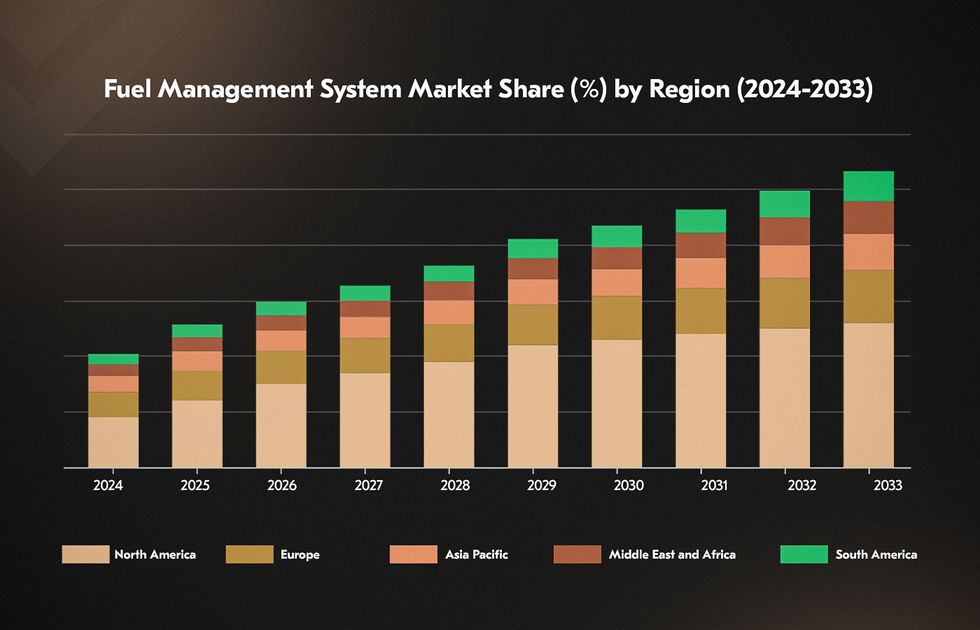

- The fuel management system market is valued at $624.4 billion in 2024 and is expected to grow at 4.5% annually, driven by rising fuel prices and sustainability goals.

- Electric fleets, AI-driven telematics, and connected mobility solutions are reshaping fleet operations, reducing reliance on fossil fuels, and optimizing vehicle utilization.

- Automated tracking and reporting of carbon footprints help fleets comply with environmental regulations, optimize fuel efficiency, and align with global sustainability initiatives.

With the growing time-sensitivity in the industry, fleet operators had to keep their businesses afloat amidst the economic recession caused by supply chain disruption. And building custom fuel management software has proven to be excellent in optimizing the cost-efficiency of their operations.

After all, fuel costs form up to 40% of expenses for trucking operators along with other factors, and optimizing them is important to ensure the long-term sustainability of your business.

We know what we’re talking about since Acropolium has been creating custom software for 18 years now. This includes building solutions for transportation and logistics in general and freight fleet management in particular.

Discover the market trends for the upcoming years, the value such tools can deliver for efficient fleet management, key features they must support, and the steps of building your own fuel management system.

What is a Fleet Fuel Management System?

A fuel management system combines advanced hardware and software to monitor and control a fleet’s fuel consumption. Powered by telematics, it provides real-time insights into fuel usage, helping fleet operators enhance efficiency and overall productivity.

This technology enables precise tracking of fuel consumption, leading to substantial cost reductions. It also promotes better driving practices through feedback mechanisms and accountability measures. Automated processes, such as scheduled maintenance, further optimize fuel efficiency.

Additionally, by minimizing unnecessary fuel waste, the system supports sustainability efforts by lowering carbon emissions within the industry.

The fleet fuel management system market is on a steady rise, valued at $624.4 billion in 2024 and expected to grow at a 4.5% annual rate through 2031. This surge comes as businesses look for smarter ways to cut fuel costs and improve efficiency. With fuel prices fluctuating and sustainability becoming a priority, more companies are turning to advanced monitoring solutions to optimize consumption, reduce waste, and stay competitive in an evolving industry.

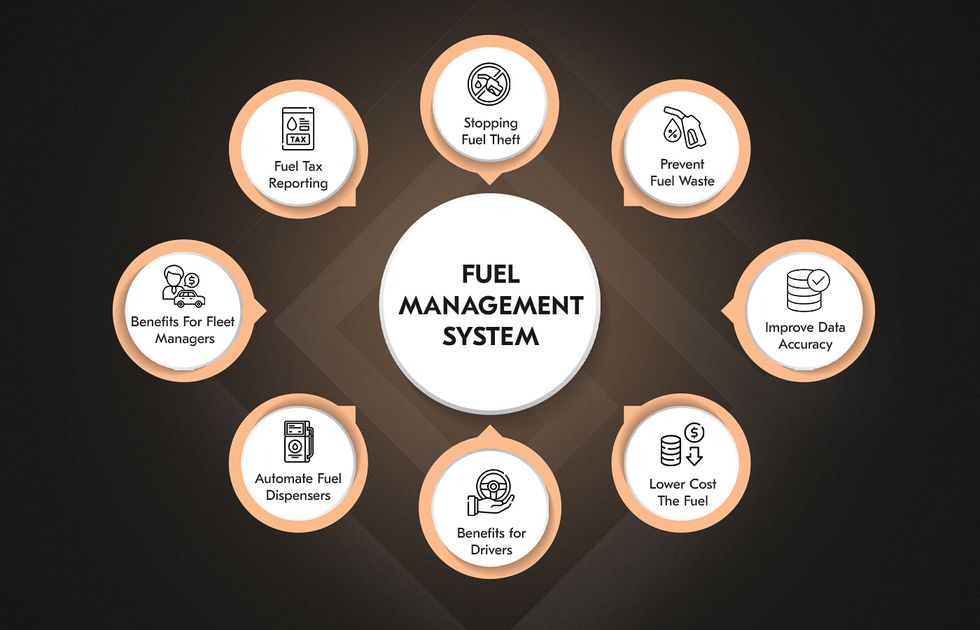

Benefits of Developing and Implementing a Fuel Management System

Cost-efficiency is the cornerstone of sustainable operations and long-term business success. Thus, creating a fuel management system for your needs (or integrating purpose-built software with your tool kit) provides multiple benefits. The most prominent of them are:

Dynamic fuel cost optimization & predictive analytics. When operating across states or borders, especially in the cold season, selecting the right fuel brand is essential for ensuring cost-efficiency. Such software can either monitor the fuel bought by the driver or recommend the best brand for the road and weather conditions ahead. Besides, it integrates dynamic pricing data and predictive analytics to recommend the best fueling stations based on price trends and consumption patterns.

Real-time route adjustments & cost savings. AI-powered fleet fuel management systems analyze real-time traffic, weather conditions, and fuel consumption for the most efficient routing. Reducing unnecessary detours and idle time, fleet operators can cut fuel expenses while ensuring timely deliveries. Such reactive adjustments lower wear and tear on vehicles, improve overall productivity, and keep operational costs in check.

AI-driven eco-driving insights. Rapid speeding, hard braking, and idling with a working engine are three major ways how drivers waste fuel. By monitoring for such occurrences in real-time, fleet operators can determine the drivers with the best driving habits (and the worst ones). At the same time, modern systems go beyond simple monitoring by using AI to deliver predictive recommendations, automated alerts, and even real-time vehicle adjustments.

Real-time fuel fraud detection. Dishonest drivers siphoning fuel or honest ones losing it due to leakage mean extra expenses. If you implement fuel card control, telematics, and fuel level logging with IoT sensors, the software will help identify fuel theft attempts and block them instantly. Live monitoring detects suspicious fuel usage patterns, such as unauthorized refueling or unexpected drops in fuel levels. With instant alerts, fleet operators can take immediate action to prevent theft and ensure every gallon is used efficiently.

Predictive maintenance and reduced fuel wastage. Advanced fuel management software anticipates maintenance requirements before they escalate into expensive problems. By analyzing engine health and fuel patterns, they identify potential issues such as leaks, low tire pressure, or mechanical faults that can drive up fuel consumption. Addressing these concerns early ensures vehicles operate at peak efficiency, cutting fuel waste and minimizing unplanned repairs.

Automated carbon footprint management & ESG compliance. Every fleet operator has to provide reports of CO2 emissions and comply with the IFTA regulation. Today, fleet solutions automate this task, ensuring accurate reporting and seamless tax compliance. Beyond simplifying paperwork, they also track carbon footprints, recommend CO2 offset strategies, and provide ESG compliance tools, helping businesses align with global sustainability goals and corporate responsibility commitments.

These are not the only benefits of using a fuel management system for your fleet, but we will talk about them in more detail later. For now, let’s look at the trends of the truck fleet market. Chances are, they will contain some features you’ll want to include in your custom fuel management system.

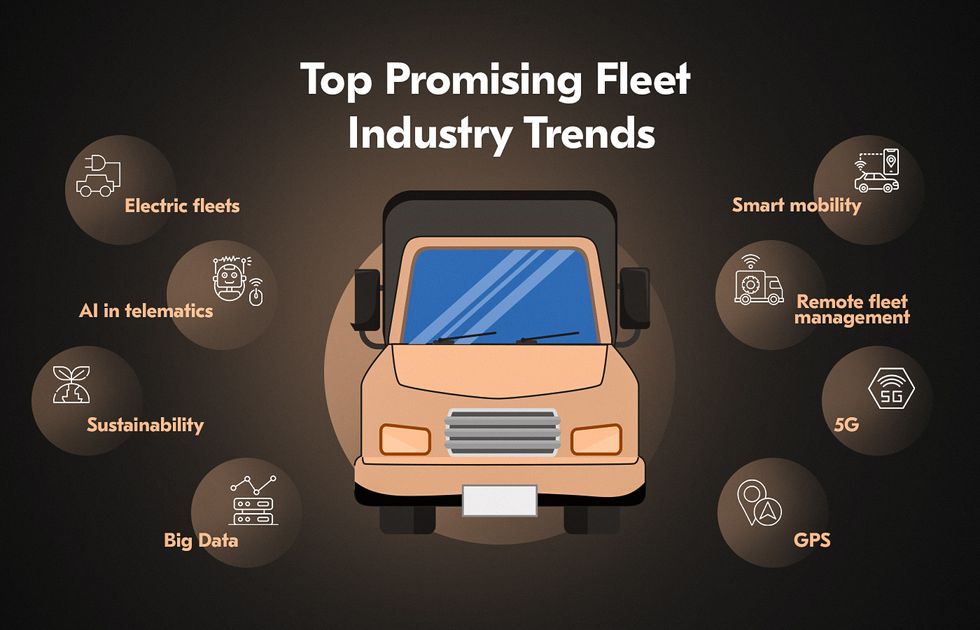

Top Fleet Industry Trends for 2025 and Beyond

Last year brought about several logistics trends that continue growing, and some of them will remain hot for decades.

The rise of electric fleets

As businesses shift toward sustainability, electric fleets are becoming a key focus in fuel management. Companies are investing in EV infrastructure, including charging networks and energy optimization software, to reduce fuel costs and carbon footprints. Advanced battery monitoring and predictive analytics help maximize efficiency and fleet uptime.

AI in telematics

Artificial intelligence is revolutionizing fuel management by enhancing telematics solutions. AI-driven insights help optimize fuel usage, predict maintenance needs, and improve route planning to reduce unnecessary fuel consumption. Machine learning algorithms analyze driving behavior, detecting inefficiencies and suggesting real-time adjustments for better fuel economy.

Renewed focus on sustainability

With stricter environmental regulations and corporate sustainability goals, fuel management solutions are prioritizing cleaner energy sources, carbon tracking, and alternative fuels. Businesses are integrating data analytics and AI for eco-friendly practices to monitor emissions and implement greener fueling strategies, aligning with global efforts to reduce environmental impact.

Making big cash on Big Data and AI

One of the AI use cases in transportation lies in the ability to centralize, aggregate, and analyze the wealth of data generated by your fleet and external sources. So, you will be able to detect negative patterns and make informed decisions that will help reduce expenses.

This way, your company can turn a useless pile of reports into a powerful driver for business development and innovation, which can positively impact your bottom line.

Embracing smart mobility

The integration of IoT, connected vehicles, and shared mobility solutions is reshaping fuel management. Smart mobility systems use real-time data to optimize fuel efficiency, reduce idle times, and enhance vehicle utilization. For example, in developed countries, the MaaS user base is projected to increase by 326% from 2023 to 2028, replacing 3.3 billion private car trips.

Innovations like dynamic routing and energy-efficient driving strategies are helping fleets minimize fuel waste and operational costs.

Remote fleet management

A fuel management system should be only a part of a remote fleet management system. Ran as a SaaS platform in the cloud, it ensures seamless connectivity between the driver’s mobile app, Electronic Logging Devices (ELDs), and various sensors aboard the truck, fueling equipment at gas stations, and the management dashboards running the whole operation.

5G adoption looms on the horizon

With Elon Musk launching more and more Starlink 5G satellites, the worldwide 5G Internet coverage is getting closer every day. Low latency means fewer communication inconsistencies, more stable data transfer, real-time notifications, and more.

This is crucial for truck managers and fleet operators, who need to stay in control of the situation 24/7. Modern freight forwarding systems are built to support both 4G and 5G communication standards, so early adoption will help you stay ahead of the competition.

GPS and telematics pave the way

From vehicle location tracking and in-cab video surveillance to real-time engine performance monitoring, GPS and telematics deliver immense value to fleet operators. This includes staying connected with drivers anywhere, informing them of the changing weather conditions on time and offering alternate routes, controlling preventive maintenance of every vehicle, etc.

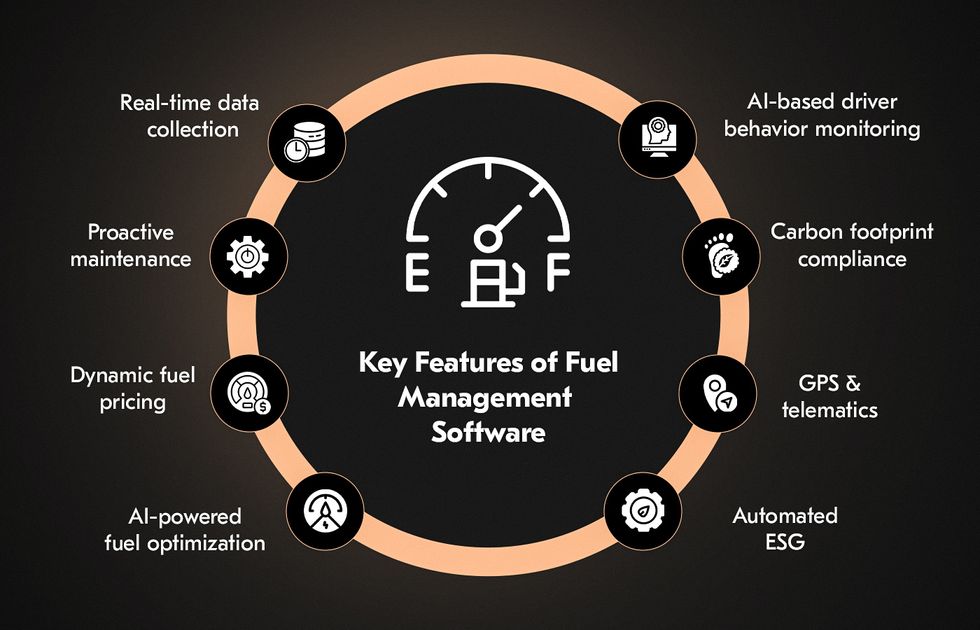

Key Features of Fuel Management Software

The main fuel management system features will help you save fuel, predict maintenance, and stop fuel theft.

AI-based driver behavior monitoring

By noticing speeding and braking occurrences through various AI-powered and IoT sensors, fleet managers are able to identify good (and suboptimal) fuel consumption cases based on driving habits.

One of the most important fuel management system features is around-the-clock monitoring of all the trucks in your fleet, in addition to detailed reports and logs. This way, you can receive alerts in real-time when the driver is speeding or idling and can set up notifications for them.

Real-time data collection

Real-time data collection helps fleet managers monitor fuel usage, refueling, and vehicle consumption instantly. It detects inefficiencies, prevents fuel theft, and ensures compliance. Live tracking enables quick responses to irregularities, optimizing fuel costs and improving operational efficiency.

Proactive maintenance instead of reacting to breaks

A truck stuck 60 miles away from the nearest city with a broken engine is the fleet manager’s worst nightmare. Relying on drivers to perform full diagnostics and maintenance of their trucks on the road is not the best decision.

By examining the data from multiple sensors in the engine and other truck systems, fleet operators can be alerted about the upcoming malfunctions and fix them proactively.

Dynamic fuel price optimization

AI-driven fuel price optimization identifies the most cost-effective refueling stations based on real-time data. It reduces expenses, improves budgeting, and enhances profitability by factoring in fluctuating prices, discounts, and regional taxes.

AI-powered fuel optimization

By using GPS tracking and features like telematics, fuel management systems allow determining vehicle location and tracking its fueling spots to prevent fuel theft and leakage.

The system can calculate the amount of fuel needed to go from point A to point B and allocate this amount to the fuel card at the fueling depot. It can also tell when a fuel purchase record comes from a station where none of your fleet vehicles has ever been, prompting that the fuel card data was probably skimmed.

GPS & telematics integration

The integration of GPS and telematics allows for tracking vehicle location, monitoring its speed, and fixing routes on the go. It reduces fuel waste, prevents fraud, and enhances efficiency by analyzing driving behavior and minimizing unnecessary idling.

Automated ESG & carbon footprint compliance

CO2 emission taxation and IFTA reporting form quite considerable expenses for large fleets. By basing your reports on in-depth data from a fuel management system, you will be able to compile these reports quickly, in an error-proof and reliable manner.

The software will compile data from different dashboards to provide a unified overview of your operations and save you a ton of time, effort, and money.

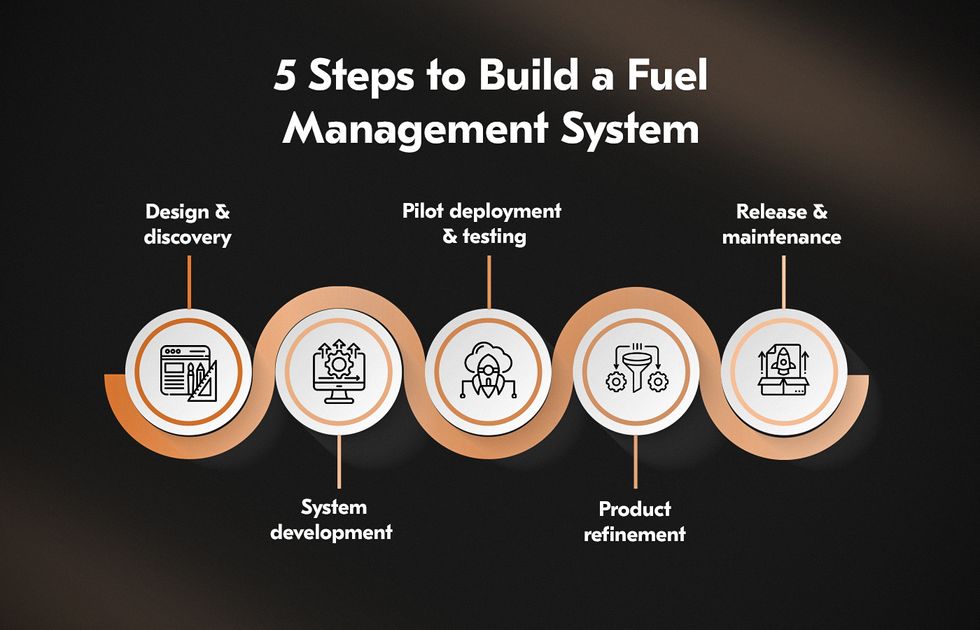

A Step-by-Step Guide to Building a Fuel Management System

There are several important stages of building a custom fuel management system. Here, we will briefly explain the stages of the process and what each step brings to the table.

Product discovery and design

If you decide to build fuel management software from scratch, you will need to account for all the tools that will have to interact with it, both physical (hardware and sensors) and digital (software).

After learning the technology behind the tools you already have, the sensors and hardware you will have to install, and the user stories of the future product, the development team will design and prepare a clickable prototype. This will allow the developers to showcase the potential use scenarios and adjust workflows if needed. At the end of this phase, you will have a development roadmap, a prototype, and an approximate estimate.

System development

At this stage, the team finalizes the selection of the technology stack needed to build custom fuel management software, the roadmap ahead, and the expected estimates. Then the development begins, often simultaneously with installing the required equipment on your fleet and configuring it.

You will generally need a mobile app for drivers and a cloud-based web app for managers/data analysts. Don’t worry, your development team will know what to do. And if you don’t currently have access to such expertise, Acropolium will gladly lend a helping hand.

System pilot deployment and testing

Once your custom fuel management system is built, it should be tested with a pilot project before rolling it to the entirety of your fleet. The pilot will help ensure the possible mistakes are fixed, and your employees get acquainted with the platform before it’s being actively used.

Release and ongoing maintenance

After the bugs are ironed out, the software can be released for all the fleet to be used in daily operations. Then, maintenance and ongoing development begin while you enjoy the benefits of having a custom fuel management system.

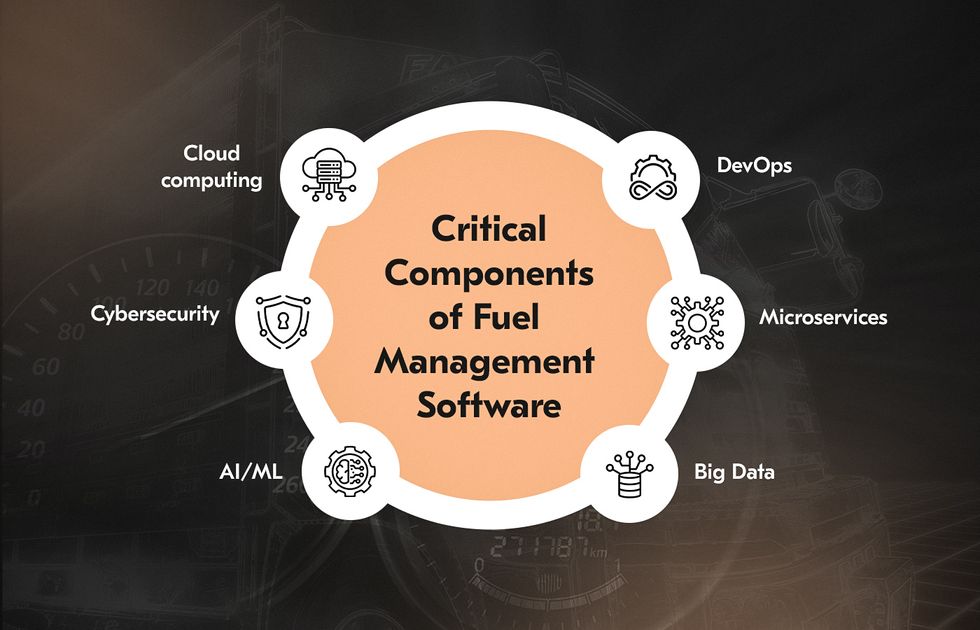

Under the hood: Components of a Fuel Management System

When building custom fuel management software, consider cloud, DevOps, microservices, Big Data, AI/ML, and cybersecurity.

It’s critical for you to understand the essential components that form robust, secure, reliable, and scalable software.

Cloud. Such software must naturally run in the cloud to ensure the required accessibility and scalability of operations. Your development team will choose between AWS, GCP, and Microsoft Azure, depending on many individual factors. Hybrid cloud solutions are gaining traction, offering a balance between on-premise control and cloud flexibility. Meanwhile, edge computing enables real-time data processing closer to fuel stations or fleet operations, reducing latency and improving efficiency.

Cybersecurity. Fleet fuel management software is now a prime target for cyber threats, making robust blockchain-based encryption, access control, and threat detection essential. Implementing zero-trust architectures and proactive monitoring safeguards sensitive fuel data from breaches and cyberattacks.

DevOps. The software development team should consider implementing CI/CD to minimize the manual effort needed to deliver updates and new features.

Microservices. Going with the microservices architecture will allow you to be more scalable and resource-efficient than with a monolith app. Plus, it ensures better operational resilience as various software parts can be launched, rebooted, or updated independently.

Big Data analytics. Gathering data from thousands of sensors is pointless if you don’t plan on analyzing it.

AI/ML. Machine learning algorithms allow detecting the patterns that are hard to identify manually and uncovering hidden expenses, as well as room for growth.

Developing Fuel Management Systems With with Acropolium

With a proven track record of 23+ comprehensive solutions, including fuel management systems, Acropolium is a reliable partner for businesses seeking efficiency, security, and cost optimization. Our expertise spans AI-driven analytics, telematics integration, and dynamic fuel price optimization, ensuring cutting-edge solutions tailored to your objectives.

We specialize in building scalable, future-proof systems that enhance fleet performance while supporting sustainability goals. Trust Acropolium to deliver innovative, high-performance software that seamlessly integrates modern technologies, optimizing fuel usage and operational efficiency.

Final Thoughts

Fuel management systems are quickly becoming a must-have for fleet operators who want to save money, improve efficiency, and meet sustainability goals. With AI, IoT, and cloud tech advancing, businesses that invest in smart fuel management will stay ahead of the competition while keeping costs low and operations smooth.

Acropolium has all these points covered thanks to our in-depth expertise in transportation and fleet management solutions. Book a consultation or simply contact us, and we will gladly help you build fuel management software that’s uniquely tailored to your needs.

![Cloud Computing in Logistics and Supply Chain [2025 Guide]](/img/articles/cloud-computing-in-logistics-and-supply-chain/img01.jpg)

![6 Use Cases of AI in Transportation and Logistics: [2025 Edition]](/img/articles/ai-in-transportation/img01.jpg)

![Logistics & Shipping APIs Integration Guide [2025]](/img/articles/logistics-and-shipping-apis/img01.jpg)

![IoT for Supply Chain Businesses: [6 Use Cases Included]](/img/articles/iot-for-supply-chain-management/img01.jpg)