Key Takeaways

- Real-time supply chain visibility is a top driver, with 92% of businesses reporting better transparency after implementing IoT.

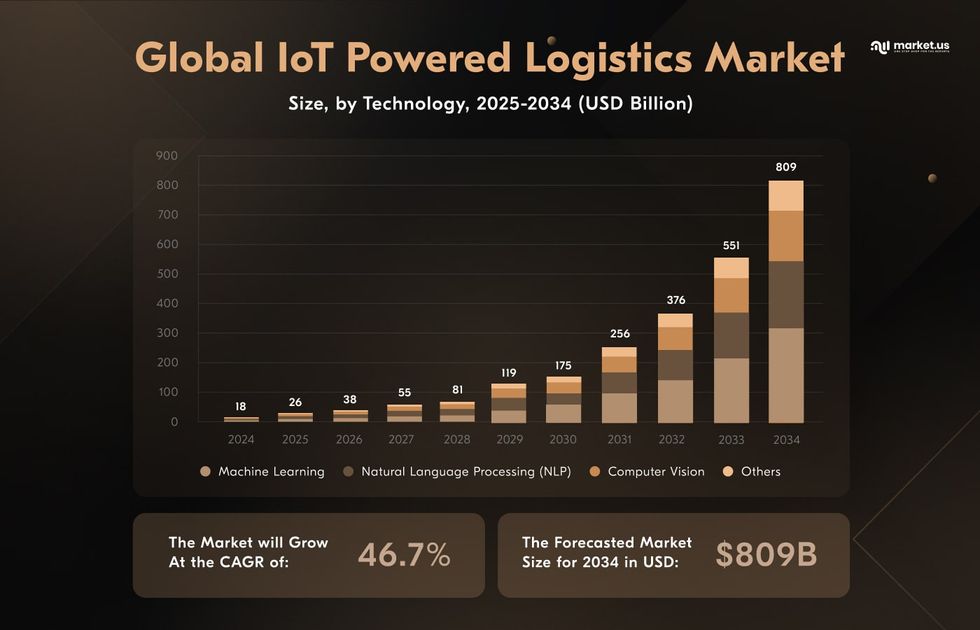

- The global IoT supply chain/logistics market is projected to jump from $26B in 2025 to $809B by 2034, signaling massive long-term investment.

- Predictive maintenance powered by IoT and AI extends equipment lifespan by detecting issues early, cutting unexpected interruptions, and reducing long-term operational costs.

- Acropolium’s IoT solution delivered measurable business impact, including 20% less system downtime, 15% lower inventory expenses, and 22% higher customer retention.

Supply chain and fleet management involve coordinating every step of getting a product from the manufacturer to the customer. This includes sourcing materials, production, transportation, and delivery. Because the industry relies on multiple moving parts working in sync, the IoT in supply chains plays a key role.

88% of businesses said IoT was either integrated into several areas of their operations or played a central role in driving digital transformation.

As a recognized top IoT developer, Acropolium has helped businesses from different industries adopt interconnectivity for greater efficiency. In this article, we want to explore the real-world IoT solutions for supply chain businesses, their benefits, challenges, and practical applications for 2025.

What Is IoT in Supply Chains?

The Internet of Things in supply chains means connecting physical tools like sensors, RFID tags, and GPS trackers to digital logistics management systems. Together, they keep a close eye on how transportation goods move from point A to point B.

These devices gather data along the way, offering clear visibility into where products are and what shape they’re in. On top of that, IoT supply chain solutions can track how equipment is performing and monitor conditions like temperature or humidity. All this data is processed in real-time through a central platform, helping teams catch issues early and make smarter decisions faster.

Standing near the most popular automotive, transportation, and logistics tech trends like AI and ML, IoT is being widely used across fundamental supply chain operations. Hence, the global market for IoT-powered logistics is set for massive growth, rising from $26 billion in 2025 to an expected $809 billion by 2034.

Benefits of IoT in Supply Chain Operations

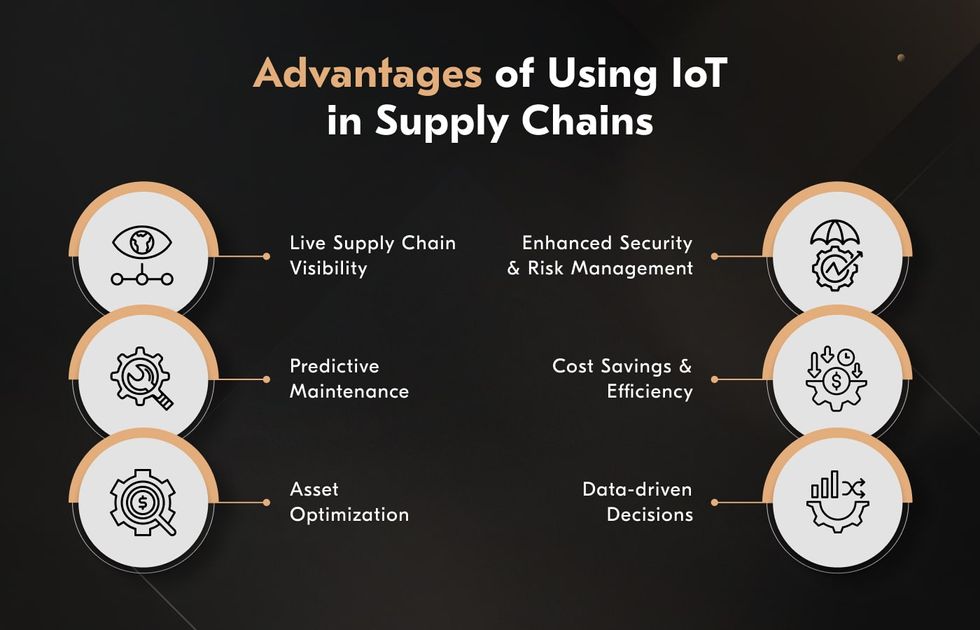

With the operational landscape growing more complex and goods passing through more checkpoints than ever, the chances of disruption are high. That’s where IoT in the supply chain steps in, offering real-time visibility and control. Let’s see how the technology helps businesses respond faster, adapt smarter, and keep operations moving, even when the unexpected hits.

Live Supply Chain Visibility

IoT supply chain devices (GPS trackers and smart sensors) stream data at every step. That live line of sight helps prevent stockouts, fine‑tune delivery routes, and keep warehouses humming smoothly. Moreover, 92% of survey respondents say that integrating IoT has led them to greater supply chain insight.

Predictive Maintenance & Asset Optimization

Instead of reacting to breakdowns, IoT sensors track machine performance in real-time, monitoring temperature, vibration, and usage. Paired with predictive analytics and machine learning, this lets you plan maintenance ahead of time, cut downtime, and extend equipment lifespan.

Smarter Inventory Management

Automated stock tracking through RFID and weight sensors means your shelves self‑report counts and reorder points. You dodge overstock or empty‑shelf scenarios, free up cash tied in surplus inventory, and stay nimble enough to seize sudden market opportunities with your IoT supply chain management.

Enhanced Security & Risk Mitigation

Connected devices build a traceable supply chain from production to final delivery. You’ll know instantly if something goes off course, whether it’s a route deviation or temperature spike. Integrated with blockchain, this traceability adds an extra layer of protection against fraud, spoilage, or theft.

Cost Savings & Operational Efficiency

End‑to‑end data flows expose hidden bottlenecks, whether it’s a slow unloading dock or an underused delivery truck. Armed with the right metrics from IoT in the supply chain tools, you can reallocate resources, optimize routes, and slash wasted labor or fuel costs, driving leaner operations and faster turnarounds.

In fact, 74% of businesses report better overall performance of their supply chain with the use of IoT.

Data-Driven Decision Making

The real advantage comes when you turn all that sensor data into strategy. With help from analytics tools and generative AI, you can predict demand surges, fine-tune logistics, and make faster, smarter calls across your supply chain.

IoT Use Cases in Supply Chain Businesses

The Internet of Things in supply chains has become essential infrastructure. They turn physical operations into sources of continuous data, enabling supply chain teams to detect inefficiencies, reduce manual intervention, and make faster, better-informed decisions.

Let’s look at how leading organizations are applying IoT in specific operational contexts, moving beyond pilots and into scalable, high-impact solutions.

Asset Tracking & Fleet Monitoring

GPS-enabled IoT devices let logistics teams track vehicles, location, condition, and delivery progress from one dashboard. Cold chain operators now rely on connected temperature sensors to keep pharmaceuticals, food, or chemicals within safe ranges across long hauls.

If anything veers out of spec, alerts go out immediately, contributing to progressive supply chain analytics strategies. That’s how DHL leverages IoT for supply chains with connected fleet systems to manage fuel consumption, detect delays early, and improve driver safety.

Smart Warehousing

Warehouses are getting smarter with RFID tags and handheld scanners that constantly update stock levels, shelf locations, and reorder points. They send the data right to supply chain management software, reducing manual counting or missed inventory.

RFID has transformed retail by enabling real-time inventory tracking and reducing losses. Global brands like Walmart, Zara, and Uniqlo use it to monitor stock, streamline operations, and boost efficiency across their stores.

IoT-powered Robotics and Conveyors

Interconnected conveyors and autonomous robots are prominent IoT in supply chain examples that speed up sorting, packing, and loading. It’s especially useful in high-volume operations like e-commerce or retail fulfillment centers. At the same time, they monitor vehicle and equipment health to support predictive maintenance.

In transit, IoT systems detect shock, temperature shifts, and unauthorized access, triggering immediate alerts to prevent losses. Amazon’s newest fulfillment centers operate with 1 million robots, IoT-connected conveyors, and robotic arms that handle sorting, scanning, and item movement.

Predictive Maintenance

Sensors embedded in machinery and delivery trucks track real-time metrics like engine temperature, vibration patterns, and runtime. Combined with predictive algorithms, they flag early warning signs of wear or failure, letting teams schedule fixes before issues hit.

Such applications of IoT for supply chains are already making a difference in sectors like manufacturing, agriculture, and transport, where uptime is everything. For example, Siemens integrates predictive analytics with IoT sensors in industrial equipment to reduce unplanned interruptions.

Demand Forecasting & Inventory Optimization

IoT-enabled shelves and delivery systems feed data back to central systems, showing exactly what’s moving and when. This lets retailers and distributors align inventory with demand, reduce excess stock, and adapt faster to seasonal or regional shifts. In fashion, grocery, and consumer tech, it’s helping avoid both lost sales and overstock headaches.

Walmart uses IoT supply chain data from shelves and delivery fleets to power AI-driven forecasting models, cutting stockouts and trimming excess inventory across thousands of stores.

Supply Chain Risk Management

From shock sensors on fragile cargo to humidity trackers in electronics shipments, IoT tools are helping teams monitor environmental conditions throughout the journey. Prompt alerts for route deviations or tampering attempts give you time to react, protecting not just your products but your bottom line and customer trust.

Maersk attaches these sensors to refrigerated containers, ensuring alerts trigger the moment conditions deviate, helping avoid spoilage.

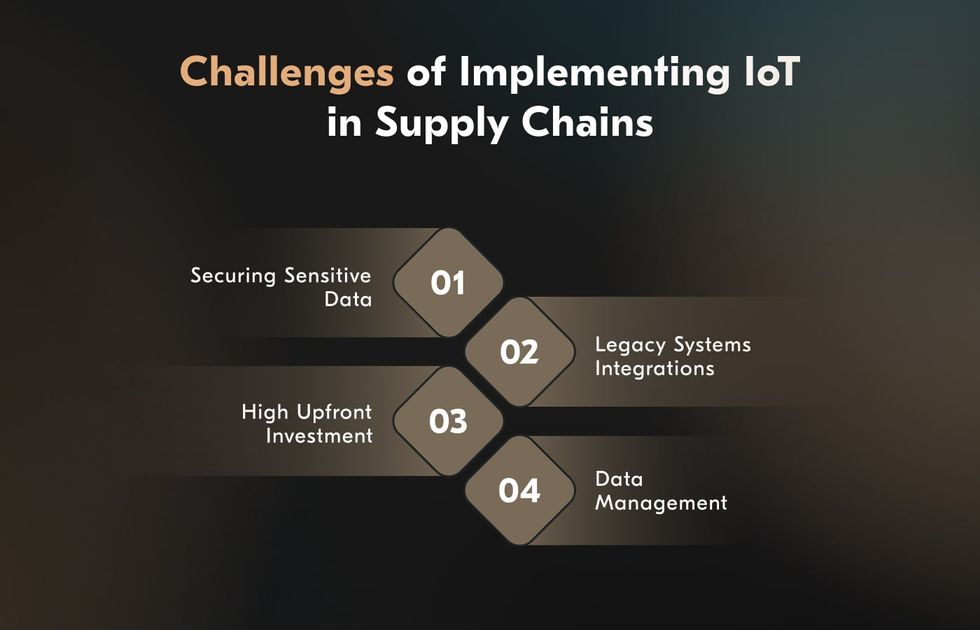

Challenges of Implementing IoT in Supply Chains

Even with all the benefits of IoT in supply chains, rolling it out isn’t always smooth. One of the biggest sticking points is plugging modern IoT tools into older systems. Lots of companies still rely on legacy infrastructure that wasn’t built to talk to smart devices, which can lead to serious integration headaches and workflow disruptions. That’s where you’ll need to partner with a seasoned development team or an IT outsourcing provider who has experience with handling common issues.

Securing Sensitive Data

As IoT supply chain devices collect tons of confidential information from across the supply chain, the volume and sensitivity of data increase dramatically. This, in turn, raises serious concerns around privacy, data ownership, and vulnerability to cyberattacks.

Without strict security protocols, like encrypted data flows and secure blockchain-based access controls, companies risk breaches that could expose both operational data and customer information.

Solution

Encrypt data at every level: device, network, and cloud. Implement zero-trust architectures and role-based access controls. Combine with blockchain for tamper-proof audit trails. Regular security audits and firmware updates are essential to patch vulnerabilities.

Integration with Legacy Systems

Many supply chains still run on older legacy systems that wern’t initially designed to interact with smart devices. Connecting modern IoT solutions for supply chains to aging ERP or WMS software often requires costly middleware, system upgrades, or customized APIs. This lack of compatibility slows down adoption and can complicate data flow between systems.

Solution

Use API gateways, middleware, or IoT integration platforms like Azure Logic Apps or Zapier for seamless connection between old systems and new IoT supply chain components. Gradually phase out outdated infrastructure through a hybrid integration model to avoid disruptions.

Upfront Investment Challenges

Implementing IoT involves cloud infrastructure, data analytics platforms, integration services, and often, network upgrades. For businesses with complex global operations, these initial expenses can feel prohibitive, even if the long-term ROI is strong.

Solution

Start small with pilot programs focused on high-impact areas like fleet tracking or warehouse automation. Use low-code development platforms to build scalable dashboards and workflows without a full engineering team.

Turning Raw Data into Insight

IoT in supply chains generates loads of information, but turning that data into clear insight is a challenge. Many organizations struggle to manage data pipelines, filter out noise, and implement real-time analytics that actually support decision-making. Without a proper strategy and big data management, value is easily lost in the noise.

Solution

Adopt AI-powered analytics platforms that automatically flag anomalies and suggest optimizations. Use edge computing to pre-process data closer to the source, reducing cloud storage expenses and speeding up decision-making. Implement dashboards with real-time KPIs relevant to supply chain ops.

Scalability and Device Management

When IoT networks grow, companies face mounting complexity in managing thousands of devices across geographies. Ensuring devices are updated, secure, and connected consistently is a growing operational burden. Without scalable cloud-based infrastructure and centralized control, performance and reliability quickly suffer.

Solution

Deploy centralized IoT solutions for supply chain device management that automate provisioning, monitoring, and firmware updates. Design scalable network architectures from the start, and use modular frameworks so that adding new features or devices doesn’t require rebuilding your system.

Why Choose Acropolium? (Case Study)

Recognized for our supply chain development services by Clutch, our dedicated teams take a client-centric approach to each project, ensuring their data is safe and compliant. We use the latest technologies and flexible infrastructure to bring to life products that address modern challenges and turn supply chain data into actionable insights.

Following ISO-certified practices, we have developed and modernized over 23 solutions. When developing custom supply chain analytics software, we equipped the client’s tool with IoT, big data, and ML modules.

We built a supply chain analytics solution powered by IoT supply chain sensors, machine learning, and big data integration. Real-time tracking, predictive analytics, and automated inventory insights were centralized in one platform, with secure access and intuitive dashboards.

Results

- 20% reduction in system downtime

- 27% gain in operational efficiency

- 15% drop in inventory costs

- 22% rise in customer retention through personalized, data-driven service

Final Thoughts

Introducing IoT for supply chain management takes preparation and effort, especially when it comes to data privacy and cost considerations. But being aware of the challenges, as well as the potential benefits, and partnering with the right professionals can turn this transformation into a future-proof journey.

And Acropolium is here to make it happen while sticking to your goals and budget. Whether you need to revamp your existing tools or require a solution from scratch, our subscription-based cooperation has a plan for your objectives.

Contact us today to merge the Internet of Things and supply chain success!

![ᐉ Big Data in Logistics: Key Benefits [5 Real Use Cases]](/img/articles/big-data-in-logistics/img01.jpg)

![Warehouse Automation Systems [8 Benefits for Your Business]](/img/articles/warehouse-automation-systems/img01.jpeg)

![Shipping Management System Development ☑️ [2025 Guide]](/img/articles/shipping-management-system/img01.jpg)

![AI Route Planning in 2025: [Use Cases & Benefits]](/img/articles/ai-route-planning/img01.jpg)

![Logistics Management System [2025 Guide]: Use Cases Included](/img/articles/logistics-management-system/img01.jpg)