Key Takeaways

- Big data analytics in logistics helps transportation companies optimize routes and schedules in real-time, improving overall efficiency with smart data-driven decisions.

- Implementing big data in logistics and transportation enables agility and visibility, allowing logistics providers to monitor inventory, track shipments, and respond to disruptions promptly.

- The 2024 Inbound Logistics Report says 92% of 3PL providers use big data-driven TMS, and 83% are prioritizing visibility into orders and inventory.

- Personalized services, accurate data-based delivery estimates, and order customization enhance customer experience.

An efficient supply chain today needs to access real-time data, analyze it and enable quick decisions. According to the latest survey, 68% of supply chain businesses focus on supply chain transparency and digitalization. Big Data in logistics helps to automate the execution of all these stages, improving performance across the end-to-end value chain.

As a result, fulfillment specialists improve operations efficiency, businesses provide faster and transparent shipments for less cost, and customers are satisfied with timely service.

“Collecting data is of prime importance for the logistics company. For instance, you need info about the vehicle’s condition, the road it travels, and fuel consumption. Data about the number of drivers, their well-being, the time it takes them to leave the warehouse will also come in handy. All this information can help decide on the areas and means of optimization”, says Oleksii Glib, CEO at Acropolium.

In this article, we want to share our expertise, discussing how logistics & supply chains can benefit from Big Data, how to choose bespoke software, and why this task is so challenging.

How Is Logistics Using Big Data?

Big data in logistics refers to the collection, processing, and analysis of complex datasets related to logistics management operations. You can use sensors, GPS devices, RFID tags, and enterprise resource planning (ERP) systems. A comprehensive approach improves transportation, inventory, warehouse management, demand forecasting, and supply chain optimization.

Most transportation companies already employ a data-driven approach to decision-making. According to the 2024 Inbound Logistics Report, the majority of 3PL providers employ big data-based TMS (92%), while 83% of companies are focusing on visibility of orders and inventory.

The full potential of Big Data in the logistics industry is yet to be harnessed. Firstly, it can help to utilize maximum resources and improve transparency, thus enhancing operational efficiency. For instance, automated transportation management systems use intelligent software which controls the fleet, schedules shipments, and automates routine tasks.

Secondly, this innovation can assist businesses in improving customer experience by maintaining customers’ loyalty and retaining them. On top of it, implementing an effective data-driven business model results in increased revenue.

Big data supply chain analytics provides real-time operation visibility. Thus, logistics companies can monitor inventory levels, track shipments, and identify potential disruptions. The outcome is improved supply chain agility and responsiveness.

Also, logistics companies can use big data to predict equipment failures and maintenance needs. Try it to reduce downtime, increase equipment utilization, and extend the lifespan of assets.

The Impact of Big Data in Logistics

Implementing this new technology in your business processes may be costly, time-consuming, and complex. However, the use of big data in logistics has significant advantages. Let’s look at how Big Data impacts logistics:

Machine Learning

Machine learning (ML) algorithms identify patterns and trends in logistics data, such as delivery times, transport routes, and inventory levels. What can an analysis of these patterns give logistics companies? Optimized operations, improved supply chain visibility, and streamlined data-driven decisions.

Artificial Intelligence

Artificial Intelligence (AI) automates logistics scheduling and routing. By using predictive analytics, AI helps logistics companies anticipate potential problems and mitigate these risks. For example, big data in warehouse management leverages AI to optimize warehouse layouts, fleet routes, and inventory management processes.

Internet of Things

Internet of Things (IoT) sensors collect real-time data on shipments, vehicles, and warehouse operations. Analyze this information to optimize supply chain visibility and improve decision-making. For example, IoT sensors track inventory levels, monitor the condition of goods in transit, and maximize the use of warehouse space.

Key Benefits of Big Data in Logistics

By integrating supply chain and data analytics, logistics companies get many benefits. Let’s discuss the most crucial ones:

Demand Forecasting

Big data fosters accurate demand forecasting by analyzing historical trends, seasonal fluctuations, customer behavior, and market dynamics. Such insights help logistics companies anticipate stock levels, avoid overstocking or understocking, and better align supply with demand.

Accurate forecasts ensure smoother operations and reduce unnecessary transportation and warehousing costs.

Route Optimization

Big Data technology can help to find the best route for delivery. Analyzing data from sensors in vehicles as well as weather reports and traffic updates, advanced logistics software can help to select the optimal course of action. As a result, the companies can save a great deal of money, mostly due to reduced fuel consumption.

Improved Transparency

Big data analytics in supply chain, together with GPS devices and other tracking tools, allow logistics companies to monitor the movement of goods in real-time. That information is combined with traffic data, fleet data, and on-road network data. As a result, logistics managers can easily plan and schedule deliveries, considering predictions about weather conditions or accidents.

Using big data helps logistics companies gain insights into their supply chain management to identify bottlenecks and streamline operations. Enhanced transparency increases customer satisfaction by providing real-time tracking information and building customer trust. As a result, using big data in shipping enables risk mitigation and drives better outcomes.

The result is not only increased efficiency of logistic operations but more real-time updates for the customers and partners. They can monitor the delivery status of parcels in real-time. Moreover, the customers get automated notifications if any delay is expected.

Lower Expenses

Intelligent data analysis supports smarter decision-making that directly impacts the bottom line. From optimizing routes and improving fuel efficiency to minimizing manual processes and preventing vehicle breakdowns, analytics reduce operating costs at every level. Better demand forecasting and inventory control also contribute to cutting excess spending.

Enhanced Operational Efficiency

Big data helps eliminate inefficiencies by uncovering weak points across logistics processes, whether in transportation, warehouse management, or scheduling. By continuously refining operations based on data-driven insights, logistics companies can improve workflows, reduce delays, and scale their services more effectively.

Predictive Maintenance & Driving Optimization

Advanced analytics systems can dig into the driving habits such as speeding up, braking, driving time, etc. Some inefficient practices can be spotted and weeded out. On top of it, the data about fleet conditions allows companies to conduct maintenance in advance. The result is reduced fuel consumption and fewer delays due to vehicle breakdowns.

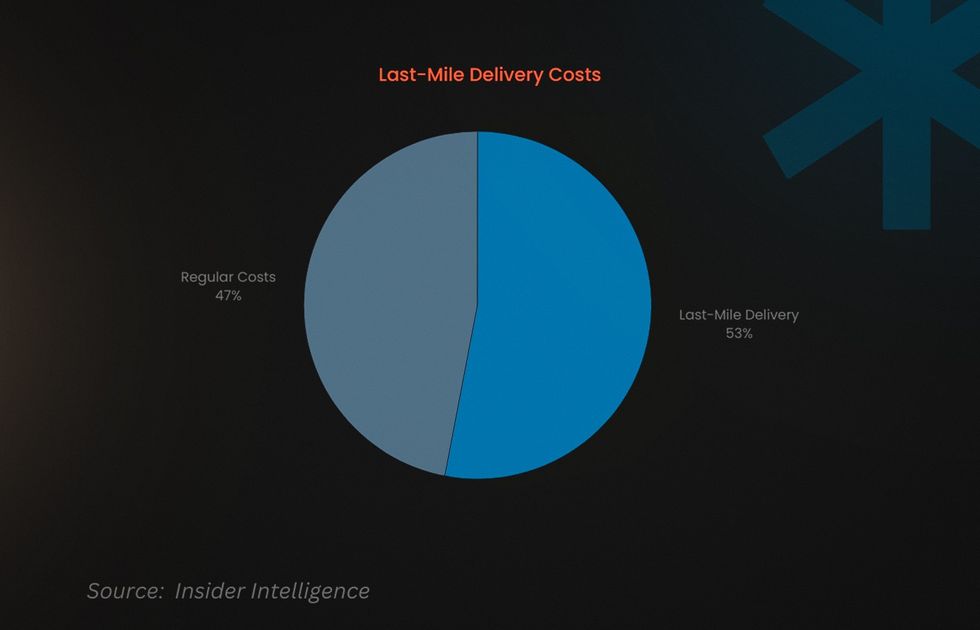

Smooth Last-mile Delivery

Last mile delivery costs represent 50% of the total shipping expenses. Big Data in logistics can help analyze the information about all stages of the delivery process, including the last mile. As a result, logistics companies detect specific patterns to optimize their delivery strategies.

AJOT sees great promise in digital twins, based on big data, as they can predict the behavior of assets and systems, simulating and optimizing route management.

Efficient Warehousing

Big Data provides warehouse managers with detailed insights into the process of loading, carrying, and unloading goods. On top of it, they understand the change in customers’ behavior changes and expectations from supply chain managers and manufacturers. This information allows managers to improve routes and scheduling deliveries, boosting warehouse throughput.

Real-time Tracking and Management

With live tracking, logistics companies can identify and proactively mitigate potential delays, minimizing costs associated with disruptions and delays. By optimizing routes and schedules based on real-time big data in supply chain, logistics companies improve shipping management and reduce time and fuel consumption.

Supply Chain Visibility

Beyond tracking shipments, big data offers a comprehensive view of the entire supply chain ecosystem. Companies can analyze supplier performance, monitor logistics partners, and gain insights into each handoff point. This holistic visibility enables more resilient and agile supply chain strategies, especially during disruptions.

Improved Responsiveness and Customer Experience

Big data analytics in the supply chain & logistics has a profound impact on its performance. A responsive supply chain allows companies to meet consumer expectations delivering quality products on time. Big data analytics helps managers understand the market situation, predict its future state, segment customers, and find new sales opportunities. In the end, the logistic companies get more control over inventory and more satisfied customers.

Big Data Use Cases in Logistics

To understand the potential of this new technology for the transportation industry, let’s look at three examples of application of Big Data in supply chain management & logistics.

Warehouse Automation by Amazon

The advancements in robotics, Big Data, and the Internet of things make smart warehouses real. Amazon fulfillment centers provide vivid examples of logistics automation.

Today, Amazon is expanding beyond early-stage robotics by adopting Autonomous Mobile Robots (AMRs), robot-to-robot communication, and AI-powered micro-fulfillment centers. Generative AI supports dynamic inventory planning, forecasting order volumes based on historical and real-time data. Additionally, edge computing enables real-time decision-making on the warehouse floor, minimizing latency and optimizing throughput.

Big Data technologies are of top importance in operating such warehouses. The algorithms have to process huge amounts of data to choreograph hundreds of robots. They determine how many bots should be deployed, which routes they should use, how fast they should move, etc. Complex simulations are run to determine the optimal parameters.

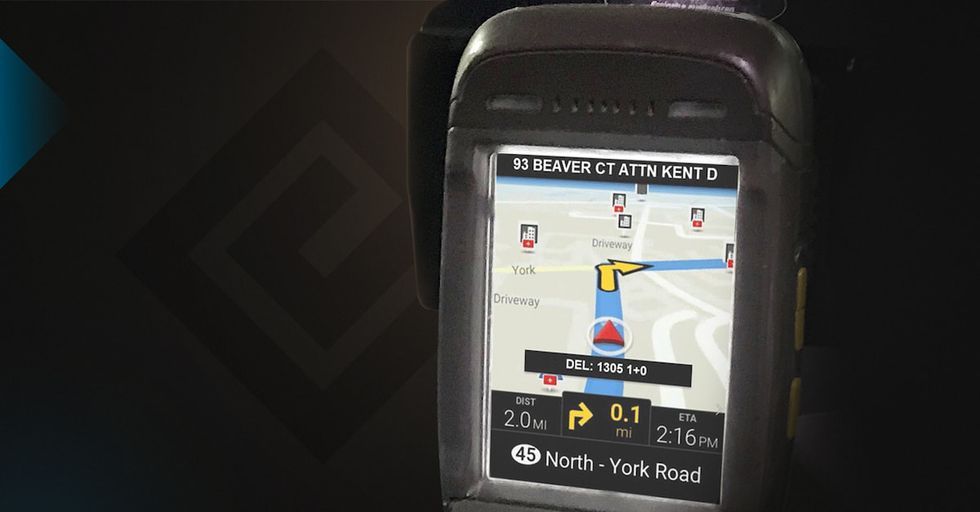

On-Road Integrated Optimization and Navigation Technology (ORION) by UPS

UPS, one of the largest shipping couriers globally, began testing its ORION algorithm in 2003, but it was deployed only in 2012. In 2019, the company added UPSNav to its route guidance platform. UPSNav provides turn-by-turn directions to guide drivers to specific package pickup and drop-off locations near the recipients, even if they are not visible from the street. ORION implementation resulted in a route reduction of eight miles per driver.

UPS is now enhancing ORION with AI for smarter routing, factoring in safety, fuel use, and delivery priorities.

Startups like Gatik and Routific are pushing further with AI-powered predictive routing, carbon reduction models, and autonomous delivery fleets. While ORION is enterprise-proven, UPS is expanding into these areas to stay competitive.

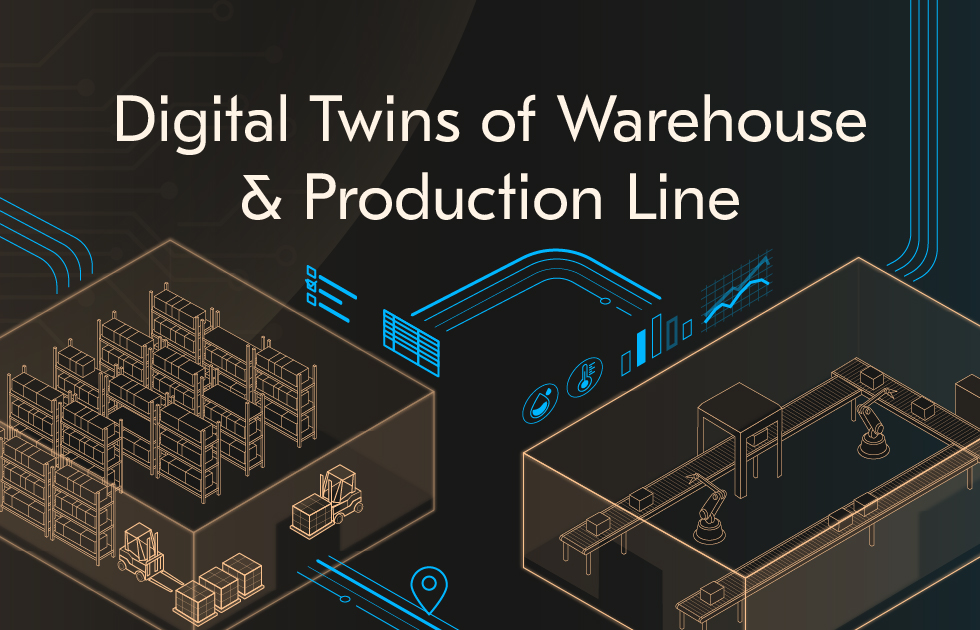

DHL’s AI-Driven Fleet Management and Digital Twin Logistics

In 2024, DHL Supply Chain began integrating generative AI into its transportation management systems to enhance planning, reduce costs, and improve service levels. The AI dynamically analyzes vast data sets like vehicle performance, weather, traffic, and delivery demand to optimize routing and dispatching decisions in real time.

DHL is also leveraging digital twin technology to simulate fleet operations, model “what-if” scenarios, and test route configurations without disrupting live deliveries. These simulations support predictive maintenance, reduce vehicle downtime, and boost delivery accuracy.

In parallel, DHL explores blockchain-based sensor data for tamper-proof temperature and condition monitoring, especially useful for pharmaceuticals and high-value goods.

Looking forward, DHL is assessing autonomous long-haul trucking pilots in collaboration with partners Aurora, aiming to further reduce costs and address driver shortages across long-distance freight lanes.

These initiatives reflect DHL’s transition to a data-centric, AI-powered logistics strategy, leaving legacy models behind in favor of intelligent, adaptive fleet ecosystems.

Deutsche Bahn Preventive Maintenance

DB implemented predictive maintenance by installing sensors on its trains. These devices collect data on various performance indicators, such as vibrations, temperature, and speed. The information goes to a central platform and gets analyzed using ML algorithms that identify patterns and predict equipment failures.

By using big data for transportation for predictive maintenance, DB optimized its train maintenance schedules, reduced repair costs, and minimized downtime, improving the overall service reliability. The accuracy of support planning grew, enabling the company to refocus its resources.

Today, DB is expanding this approach with AI-powered scheduling systems that automatically prioritize repair workflows and allocate resources based on urgency and operational impact. This has improved fleet availability and reduced unplanned downtime.

Generative maintenance planning tools now simulate long-term maintenance scenarios, allowing DB to model different strategies and select those with the lowest lifecycle cost and risk.

Additionally, computer vision is being tested to detect micro-cracks and structural defects on railcars and tracks, using high-resolution imaging and AI models for real-time diagnostics during inspections.

Walmart’s AI-Powered Route Optimization and Smart Logistics

Walmart has transformed its logistics network with AI-driven solutions that optimize both delivery routes and trailer packing efficiency. By integrating data from fleet sensors, GPS, traffic feeds, warehouse activity, and store-level demand, Walmart’s system dynamically calculates the most efficient routes for each shipment.

This AI-powered approach reduces fuel usage, improves delivery speed, and increases trailer utilization, minimizing empty space and the number of trips needed. The system also adapts to real-time variables like traffic congestion and weather, enabling on-the-fly adjustments to routing.

Launched in 2024, Walmart’s new Commerce Technologies logistics platform reflects a broader shift toward data-first, intelligent supply chain operations, thus boosting cost efficiency, service reliability, and sustainability across its massive retail network.

How to Choose the Right Logistics Management Software?

Transportation companies get data from a wide variety of sources, from GPS trackers to advertising response stats. However, huge unstructured datasets can impede decision-making. Businesses need technology, structuring the information and converting it into actionable insights. Therefore, having the right logistics management software is very important.

A really powerful tool should handle all aspects of transport operations. That includes inventory tracking, supply chain mapping, route optimization, warehousing improvement, etc. The characteristics of the top-notch logistics management software include:

- Real-time logistics tracking, which helps to establish transparency, improve accuracy, and exchange information

- Multi-client architecture, which can be deployed quickly and easily

- Invoicing functionality to apply and process partnership policies, manage invoices on time, etc.

- Comprehensive reporting system with access to all necessary records

The ideal instrument embraces all the functions to make your logistics and supply chain management really “smart.” Alternatively, it should seamlessly integrate with other tools and solutions. Give preference to cloud-based software to ensure its scalability and adjustability.

Note that many businesses may partner with 3PLs, cooperating with cargo carriers. Therefore, several different companies are involved in the transportation pipeline. That’s why all important partners need to be able to exchange data with each other smoothly. It contributes to the seamless coordination of their actions.

At the same time, many logistics companies have a unique set of metrics important for them. Each of those businesses may accumulate data from a different set of sensors on their vehicles. Therefore, it’s almost impossible to find a one-size-fits-all off-the-shelf Big Data software for logistics. Acropolium offers custom software development services in many areas, including transportation. We can help you with a project requiring Big Data development for logistics. Read on to learn more about our expertise.

Why Choose Acropolium for Implementing Big Data in Logistics Project

Acropolium has the expertise and experience necessary to build complex Big Data solutions for supply chain. Our agency delivered 84 software solutions for 56 clients from different spheres, including logistics. We can offer you tailor-made software for freight forwarding optimization, supply chain, warehouse management, document generation systems, etc.

To understand our background better, let’s have a look at the logistics app development cases we’ve completed for our clients.

Supply Chain Analytics Platform for a Logistics Company

Our client, a leading logistics provider, needed a powerful analytics solution to optimize operations and meet the growing demands for expedited and just-in-time delivery. Their internal systems were fragmented, and decision-making was hindered by scattered, unstructured data.

They required a centralized platform that could harness big data for more accurate demand forecasting, route optimization, and personalized customer service.

The main goals were as follows:

- Improve operational efficiency through data-driven inventory and transport planning

- Centralize data from multiple sources for a unified supply chain view

- Enhance customer satisfaction and retention with personalized insights

- Ensure compliance with data protection regulations

Our team applied advanced big data integration and analytics techniques. We built data pipelines to aggregate information from various systems into a centralized repository. Predictive analytics and machine learning models were used to enhance demand forecasting and inventory management accuracy.

We also developed intuitive dashboards for real-time performance tracking and decision-making. To protect sensitive operational data, we implemented GDPR-compliant security protocols, including data encryption and access controls.

As a result, the client received a scalable, secure supply chain analytics platform with real-time insights:

- 27% increase in operational efficiency

- 20% reduction in system downtime

- 15% decrease in inventory costs

- 22% improvement in customer retention due to enhanced service personalization

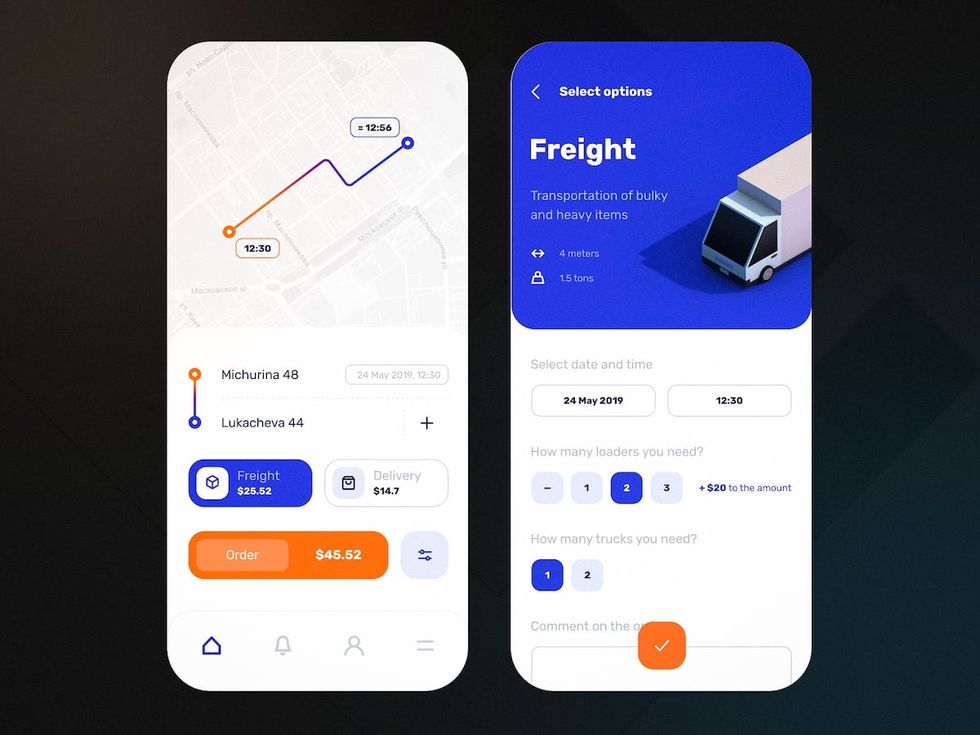

Mobile App for the Shipping Service Provider

Our client, a US logistics company, required an efficient mobile app for truck drivers and brokers to track the number of working hours. Brokers refused to pay for the extra hours, and drivers were forced to work due to external circumstances, such as vehicle breakdowns, traffic jams. Brokers suspected that the drivers were exaggerating the time required for delivery. The software solution had to solve the issue.

The main goals were as follows:

- Protect brokers from drivers overstating their amount of work

- Provide drivers with solid proof of extra hours they are required to complete the delivery

- Deliver the MVP in three months

Our developers audited the existing web solution and Android mobile application. We found several critical issues resulting in scaling, maintenance, user experience, and security problems. Our specialists optimized the core architecture, detected and fixed existing bugs. The dedicated team developed an iOS application from scratch. We completed the whole project within a tight timeframe of three months.

As a result, both brokers and drivers got a user-friendly app with maps and real-time geolocation tracking.

IoT-Based GPS Fleet Tracking App Development

A logistics software vendor asked us to refine a test prototype of a GPS tracking application. The disadvantages of the solution were the low-quality code, limiting modernization, and the unstable integration mechanism. Ultimately, it blocked displaying hundreds of trucks in real time.

We optimized the base code, increased the number of connected IoT devices to 1000, and the number of trucks displayed on the map from 100 to 1000. New features include real-time visualization of truck movement, data visualization and reporting, and remote command processing.

Improved code and new functionality make this solution one of the best GPS fleet tracking systems on the market.

Modernization of the TMS (Transportation Management System) allowed the forwarding company to improve the speed of data access, connect new functions, and increase the customer base to 1 billion shippers.

We automated document flow for an international trade software provider, validated country shipping requirements, and created order and shipping templates. It helped attract 37% more customers, reduce operating costs by 60%, and increase annual revenue by 65%.

Final Thoughts

The transportation industry faces new challenges as customers strive for higher delivery speed and transparency. At the same time, AI, IoT, and Big Data in logistics allow companies to optimize routes, reduce fuel consumption, improve warehousing, and understand consumer needs.

However, creating and implementing technologies without IT outsourcing may be tricky. Acropolium has been working with clients from the transportation industry for 8 years, and our experience in Big Data technologies allows us to address those challenges.

Contact us to unleash the full potential of Big Data for logistics in your company together.

![Logistics & Shipping APIs Integration Guide [2025]](/img/articles/logistics-and-shipping-apis/img01.jpg)

![IoT for Supply Chain Businesses: [6 Use Cases Included]](/img/articles/iot-for-supply-chain-management/img01.jpg)

![A Sustainability Transportation Guide: [Best Practices & Use Cases]](/img/articles/sustainable-transportation-practices/img01.jpg)

![The Best Route Optimization Software to Employ in [2025]](/img/articles/route-optimization-software/img01.jpg)