Key Takeaways

80% of 3PLs and 77% of shippers are actively investing in predictive analytics in supply chain operations.

91% of organizations consider AI and predictive analytics essential within the next two years, while 72% believe failing to invest in technology now could threaten future viability.

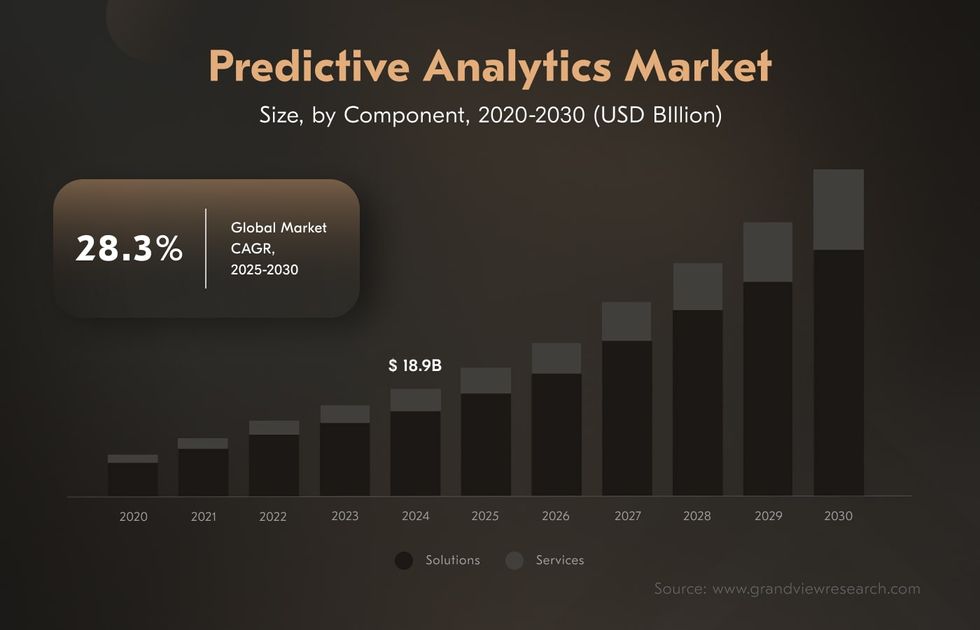

The global predictive analytics market is valued at $18.89 billion in 2024 and is projected to grow at a 28.3% CAGR through 2030.

Acrolium’s client leveraged predictive analytics and achieved a 15% reduction in inventory costs by improving demand forecasting.

Supply chain management is essential for keeping things running smoothly in any industry. Large organizations generate tons of data daily, but making sense of it all can be overwhelming. While companies have their own analytics, it’s often not enough to handle every stage of the supply chain effectively. That’s where predictive analytics for supply chain operations comes in.

Factors like market trends, forecasting, quality control, and unexpected errors can impact productivity if not properly managed. This powerful technology helps organizations stay ahead by employing machine learning and statistical models to predict future trends and potential disruptions, making supply chains more efficient and reliable.

Recognized for our top-notch supply chain and logistics solutions, Acropolium knows how powerful properly implemented AI analytics can be. Now, let’s explore its key benefits, use cases for 2025, and success stories.

What is Predictive Analytics in Supply Chains?

Predictive analytics in supply chains helps to anticipate trends like sales demand and exchange rates by analyzing historical data with statistical models. While the concept isn’t new, modern logistics technologies and advanced data mining have made it possible to process large volumes of structured and unstructured data faster than ever.

Rather than forecasting the future outright, predictive analytics identifies patterns and probabilities to present likely outcomes in logistics management. Its growing adoption is driven by digitization and the increasing dependence on big data. With the global predictive analytics market valued at $18.89 billion in 2024 and expected to grow at a 28.3% CAGR through 2030, businesses recognize its importance.

In fact, 91% of organizations see AI as crucial in the next two years, and 72% warn that failing to invest now could threaten viability.

Advantages of Predictive Analytics in Supply Chain

As demand for faster, more reliable deliveries grows, companies are turning to data-driven solutions to stay competitive. A study found that 96% of 3PLs and 86% of shippers have moved to the cloud, while 80% of 3PLs and 77% of shippers are investing in predictive analytics to make the most of IoT data.

Still, these are not the only reasons why companies leverage predictive analytics supply chain tools.

Cost Reduction through Optimized Operations

By analyzing historical and real-time data, predictive modules can optimize everything from inventory management to fleet operations. It ensures shipments are loaded efficiently, minimizes waste, and reduces unnecessary costs.

You can rebalance assets across logistics networks at minimal expense, which leads to fewer delays and more on-time deliveries.

Improved Decision-making with Real-Time Insights

Supply chain predictive analytics software is designed to track shipment statuses, monitor market trends, and predict demand. This way, logistics providers can plan weeks or even months ahead.

Transportation management systems (TMS) and supply chain management tools (SCM) powered by AI and blockchain can monitor and anticipate disruptions, allowing companies to avoid bottlenecks. Real-time data will also enhance route optimization in the future, improving the last-mile delivery success rate and making them faster and more cost-effective.

Increased Supply Chain Resilience and Risk Mitigation

With predictive maintenance, logistics managers detect potential equipment failures before they happen, preventing costly breakdowns and downtime. At the same time, advanced predictive analytics in logistics is all about managing seasonal demand fluctuations while adjusting inventory accordingly.

Enhanced Customer Satisfaction with Better Service Levels

Faster, more reliable deliveries make customers happier. Predictive analytics in transportation aims to determine demand spikes, manage delays, and maintain optimal inventory levels. With data being collected instantly, such tools ensure products are always available when needed.

Improved last-mile delivery routes contribute to minimized disruptions, which, in turn, will help you meet tight service-level agreements (SLAs) and provide a seamless customer experience.

Predictive Analytics Use Cases in Supply Chains

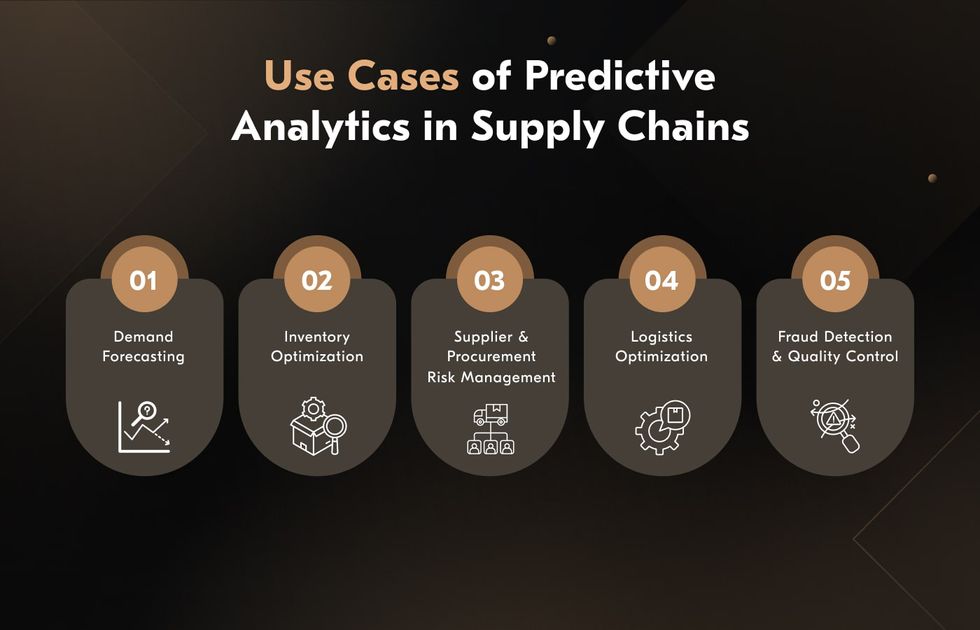

From accurately forecasting demand to ensuring quality and detecting potential fraud, predictive analysis allows companies globally to deliver better service levels to their customers. As businesses continue to adopt predictive analytics in logistics, the practical benefits of predictive analytics become increasingly clear— a smarter, more responsive, and resilient supply chain is within reach.

Let’s explore the modern predictive analytics applications in supply chains with examples from well-known businesses.

Demand Forecasting

Instead of guessing potential needs, companies can prepare in advance, ensuring they have just the right amount of stock on hand. For instance, some logistics providers use advanced supply chain analytics tools to rebalance their assets across distribution networks, reducing fuel waste and improving on-time deliveries.

Ride-hailing services like Uber also use similar techniques to adjust dynamic pricing based on predicted demand, ensuring they meet customer needs while maximizing revenue.

Inventory Optimization

One of the biggest challenges for businesses is maintaining optimal inventory levels. Predictive analytics in supply chains processes past inventory data alongside live information to pinpoint the exact amount of stock needed at various locations. Apart from reducing excess inventory, it also ensures that popular products are always available.

Retailers with multiple distribution centers, for example, can determine whether to hold inventory centrally or regionally, ultimately saving money and cutting down storage expenses. Fashion retailer Zara leverages predictive analytics to manage assets dynamically.

Using live sales data, social media trends, and customer feedback, Zara’s system predicts which products will sell the most.

Supplier and Procurement Risk Management

Supply chains operate with a network of suppliers, and any disruption has significant consequences business-wise. Forecasting machine learning algorithms assess risks by analyzing supplier performance data, market tendencies, and external factors such as weather or geopolitical events.

General Motors (GM) uses predictive analytics to assess potential supply chain disruptions by tracking supplier performance, geopolitical risks, and economic trends. The company analyzes thousands of data points to anticipate supplier failures. Such use of predictive analytics in transportation allows them to source alternative materials or partners before disruptions affect production.

Transportation and Logistics Optimization

Efficient transportation is the cornerstone of any successful supply chain. Predictive analytics enhances transportation management by analyzing traffic and weather conditions to suggest the fastest and most fuel-efficient routes.

One of the prominent examples of predictive analytics in supply chains is Walmart, which uses data-driven route planning to cut down on unnecessary mileage and lower its carbon footprint. Moreover, logistics providers use these insights to avoid bottlenecks and anticipate disruptions before they occur, ensuring timely deliveries and reducing overall transportation costs.

Fraud Detection and Quality Control

Although often overlooked, fraud detection and quality monitoring are critical to maintaining trust and efficiency in the supply chain. Predictive supply chain instruments monitor various data points — from sensor readings on shipments to supplier performance metrics — to identify unusual patterns that may indicate fraud or performance issues.

By catching these anomalies early, companies can address potential problems before they escalate into expensive errors. For example, Tesla analyzes sensor data from production lines and early vehicle performance reports to identify patterns that indicate faulty parts.

Overcoming Challenges of Predictive Analytics in Supply Chain Management

Rolling out predictive analytics across an entire supply chain is no small feat, but with the right strategy, the long-term advantages far outweigh the challenges. A well-planned approach ensures smoother adoption, better insights, and stronger decision-making capabilities.

Here are the key factors to consider when implementing predictive analytics at an enterprise level.

1. Ensuring High-Quality Data

For predictive analytics in logistics to deliver reliable results, data must be accurate, complete, and well-structured. Inconsistent, outdated, or missing data can lead to flawed predictions, affecting decision-making.

To overcome this, businesses must invest in robust data collection processes, ensure proper formatting, and use advanced data-cleansing techniques to maintain top-quality inputs.

2. Maintaining Data Privacy & Security

Predictive analytics often requires sharing sensitive business data across multiple platforms. Without strong security measures in software development, this can result in data breaches or regulatory compliance issues.

Companies, whether cooperating with web development vendors or crafting solutions in-house, must implement encryption, strict access controls, and data governance policies. It’s crucial to safeguard information while adhering to privacy laws like GDPR or CCPA.

3. Addressing Organizational Resistance

Adopting predictive analytics for supply chains often requires a cultural shift within an organization. Employees may resist new technologies due to unfamiliarity or fear of job displacement. To ease the transition, businesses should focus on change management strategies — educating teams, cooperating with dedicated teams, and demonstrating the value of predictive insights.

4. Bridging the Technical Skills Gap

Predictive analytics relies on expertise in data science, machine learning, and AI — skills that may be lacking in many organizations. Companies can address this by training existing staff, hiring specialized talent, or partnering with external developers who can help develop and manage predictive models.

5. Integrating with Legacy Systems

Many supply chain operations rely on outdated infrastructure, making it difficult to incorporate modern predictive analytics tools. Poor system compatibility can lead to inefficiencies and slow adoption. Businesses may need to upgrade legacy systems or invest in flexible platforms that support seamless logistics API integration and immediate data exchange.

Why Choose Acropolium: Case Studies

Acropolium is a trusted, ISO-certified IT outsourcing vendor that has been serving the logistics industry for 10+ years. Having delivered dozens of tech solutions for the transportation sector, we have deep expertise in AI/ML, low-code, IoT, and Big Data and how they can breathe automated transparency into workflows.

Focusing on compliant development practices, we deliver bespoke software that drives measurable growth, be it integrating predictive analytics in supply chain legacy systems or building everything from scratch.

Blockchain-Based Supply Chain Platform

An oil and gas company sought to enhance supply chain transparency and productivity with the power of blockchain. The objective was to establish end-to-end traceability, tracking products from extraction to distribution to prevent fraud, ensure authenticity, and identify process inefficiencies.

Solution

We developed a decentralized, blockchain-powered supply chain platform designed to enhance security, transparency, and performance:

An immutable ledger system to securely record every transaction and data exchange, ensuring data integrity and traceability.

Intelligent contracts to automate and enforce business rules, facilitating seamless interactions among suppliers, manufacturers, logistics providers, and distributors.

IoT integration for real-time monitoring of oil and gas movement and conditions, with secure data storage on the blockchain to prevent fraud and counterfeiting.

Advanced supply chain predictive analytics leveraging blockchain and IoT data to deliver actionable insights for better decision-making and strategic planning.

Results

Enhanced transparency with end-to-end traceability from extraction to final delivery.

Operational efficiency through smart contract automation, reducing errors and lowering costs.

Fraud prevention by eliminating counterfeiting risks and unauthorized data access.

Regulatory compliance with streamlined auditing and documentation processes.

Data-Driven Supply Chain Analytics Tool

A leading logistics company needed to enhance operational efficiency and meet customer demands for expedited shipping and just-in-time delivery. The goal was to leverage data analytics to improve service customization, optimize inventory management, and streamline transportation routes.

Our dedicated team was tasked with developing a comprehensive analytics solution to harness big data and predictive supply chain practices effectively.

Solution

We built a predictive analytics-powered platform to transform supply chain management through data-driven insights:

Machine learning for demand forecasting to analyze historical and real-time data, improving accuracy in inventory planning.

Big data integration through advanced data pipelines, consolidating fragmented information into a centralized repository for seamless data consistency.

Real-time monitoring with interactive dashboards and reports, enabling instant visibility into supply chain performance and informed decision-making.

Strong security framework with encryption protocols and access controls to ensure GDPR compliance and protect sensitive logistics data.

Results

20% reduction in system downtime, enhancing platform availability.

27% boost in operational efficiency through data-driven process optimizations.

15% decrease in inventory costs by refining demand forecasting and stock management.

22% increase in customer retention, driven by personalized service and improved delivery reliability.

Final Thoughts

Predictive analytics in supply chains is a game-changer for businesses: it helps to stay efficient while building a strong, trustworthy reputation. Logistics is all about keeping track of every stage of operations, making sure everything runs smoothly. Having the right data at the right time helps companies make sophisticated decisions and address potential challenges.

Acropolium helps businesses tap into the power of transparency and security with real-time insights, predictive modeling, and seamless integration. Our goal is to give life to custom tools that will work for your growth and budget, offering subscription-based cooperation.

Get in touch with us — let’s uncover the opportunities behind your data!

![ᐉ Uber API Integration: [Step-by-Step Guide & Use Cases]](/img/articles/how-to-integrate-uber-api/img01.jpg)

![Fleet Fuel Management System [Complete Guide]](/img/articles/build-a-fuel-management-system/img01.jpg)

![Generative AI in Supply Chain Management: [Use Cases & Solutions]](/img/articles/generative-ai-supply-chain-solutions/img01.jpg)