- Cloud Solutions

- Maps and Geolocation

- Frontend

- Backend

- DevOps

- IoT

- Optimization

- Real-Time Solution

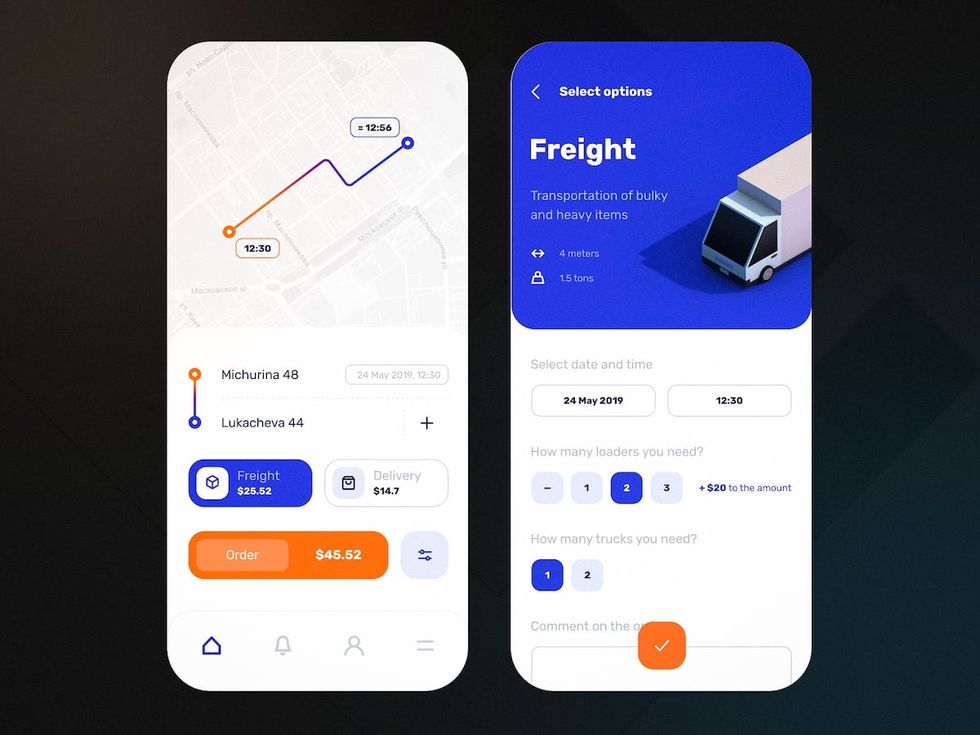

Building comprehensive GPS fleet tracking solutions with advanced truck tracking capabilities and real-time monitoring. Developing fleet tracking system with CAN bus and OBD II integration, geofencing, driver scoring and driver behaviour analysis, fuel monitoring and fuel theft alerts, ELD and IFTA compliance for USA operations, robust privacy and security, API integrations with ERP and TMS, real time map and WebSocket updates, video streaming from cameras, and automated reports exports CSV PDF.

client

3D Telematics

Malaysia

Up to 50 employees

This logistics company operates a fleet of 500+ commercial vehicles across the United States. They provide transportation services for multiple industries including retail, manufacturing, and e-commerce.

The firm earned a reputation for consistent delivery and operational excellence. Their vehicles range from long-haul trucks to local delivery and specialized transport. Their emphasis is on efficiency, with strict regard to safety and regulatory compliance in every aspect of their business.

request background

IoT-Based GPS Tracking App Development for Real-Time Monitoring

The company needed modern GPS fleet tracking technology replacing outdated systems. Their existing vehicle tracking methods relied on phone calls and manual check-ins. This created blind spots in operations. Management lacked visibility into vehicle locations and driver activities. The absence of a proper tracking system prevented data-driven decisions.

Operations required real-time vehicle location through real time map and WebSocket updates. Geofencing capabilities would monitor route compliance. The system needed driver scoring and driver behaviour analysis improving safety. FuelAxe (fuel monitoring) and fuel theft alerts are all cost cutting measures. The protocol should also be encapsulated by the higher layer CAN bus and OBD II to perform vehicle diagnostics.

Regulatory compliance was critical. The GPS fleet tracking platform had to support ELD and IFTA compliance for USA operations. Automated reports exports to CSV PDF would simplify regulatory reporting. The solution needed supporting video streaming from dashboard cameras for incident investigation.

The company wanted API integrations with ERP and TMS systems. This would connect the tracking system with existing business tools. Privacy and security measures were mandatory protecting sensitive operational data and driver information.

challenge

Secure IoT Integration and Compliance for Fleet Tracking System Development

Limited visibility and tracking. The existing truck tracking methods provided no real-time insights. Dispatchers couldn't locate vehicles accurately. The absence of real time map and WebSocket updates meant delays responding to issues. Without proper GPS fleet tracking, route optimization was impossible.

No vehicle diagnostics integration. Missing CAN bus and OBD II connectivity prevented monitoring vehicle health. Maintenance happened reactively after breakdowns. The company couldn't predict issues or schedule preventive service. This increased downtime and repair costs significantly.

Fuel cost concerns. Without fuel monitoring and fuel theft alerts, the company faced unexplained fuel expenses. Drivers sometimes idled excessively or took inefficient routes. Fuel theft at remote locations went undetected. The tracking system needed comprehensive fuel analytics.

Safety and driver management. The company lacked tools for driver scoring and driver behaviour analysis. Harsh braking, speeding, and unsafe driving went unmonitored. This created liability risks and increased insurance costs. Management couldn't identify drivers needing additional training.

Compliance challenges. Manual ELD and IFTA compliance for USA regulations was time-consuming and error-prone. Drivers maintained paper logs creating audit risks. The truck tracking system needed automating compliance documentation. Reports exports CSV PDF capabilities were missing for regulatory submissions.

Security and privacy concerns. The new GPS fleet tracking platform required robust privacy and security measures. Driver location data needed protection. The system had to prevent unauthorized access while allowing video streaming from cameras only for legitimate purposes.

Integration complexity. The company used multiple business systems. API integrations with ERP and TMS platforms were essential. The fleet tracking system needed seamless data exchange without disrupting existing workflows. Geofencing alerts had to trigger actions in other systems automatically.

goals

- Implement real-time GPS tracking with real time map and WebSocket updates providing instant vehicle location visibility. Enable dispatchers to monitor entire fleet through intuitive interfaces. Support multiple map views and vehicle grouping capabilities.

- Integrate comprehensive vehicle diagnostics through CAN bus and OBD II protocols. Build fuel monitoring and fuel theft alerts system detecting anomalies automatically. Enable predictive maintenance reducing unexpected breakdowns across the truck tracking fleet.

- Deploy advanced driver scoring and driver behaviour analysis improving safety and reducing insurance costs. Implement geofencing capabilities monitoring route compliance and unauthorized stops. Enable automated alerts for unsafe driving patterns and violations.

- Ensure complete ELD and IFTA compliance for USA operations through automated logging and reporting. Build robust reports exports CSV PDF functionality simplifying regulatory submissions. Enable drivers to certify logs electronically through mobile app.

- Develop integrated privacy and security measures that preserve private information while streaming videos from the dashboard cameras. Establish API connections with ERP and TMS systems making the dataflow between business tools as smooth as possible.

- Create scalable fleet tracking system architecture supporting growth and future enhancements. Enable real-time analytics and business intelligence through integrated dashboards. Support white-label capabilities for potential partner deployments.

solution

Comprehensive GPS Fleet Tracking with Real-Time Monitoring and Compliance

Node.js, PHP, HTML, CSS, AWS

2 years

3 specialists

We delivered advanced GPS tracking platform transforming fleet operations completely. The fleet tracking system combines real-time monitoring with comprehensive analytics and compliance features.

Real-Time Tracking Infrastructure. Built robust platform using real time map and WebSocket updates. The system processes location data from 500+ vehicles continuously. GPS coordinates update every 10 seconds providing precise visibility. Interactive maps display vehicle status, speed, direction, and driver information instantly.

Vehicle Diagnostics Integration. Implemented CAN bus and OBD II protocols reading vehicle data directly. The GPS tracking system monitors engine performance, diagnostics codes, and maintenance needs. Fuel monitoring and fuel theft alerts detect unusual consumption patterns automatically. Predictive maintenance algorithms schedule service based on actual vehicle conditions.

Safety and Compliance Features. Developed comprehensive driver scoring and driver behaviour system analyzing driving patterns. The fleet tracking system tracks harsh braking, rapid acceleration, speeding, and idling. Geofencing capabilities monitor route adherence and trigger alerts for unauthorized locations. Video streaming from dashboard cameras provides incident evidence and coaching opportunities.

Regulatory Compliance. Built complete ELD and IFTA compliance for USA operations into the truck tracking platform. Automated hours-of-service logging eliminates paper logs. The system generates reports exports CSV PDF for regulatory audits automatically. Drivers certify logs through mobile app reducing administrative burden.

- IoT Device Integration. Connected GPS trackers with CAN bus and OBD II adapters across entire fleet. Devices transmit data via cellular networks to cloud infrastructure. The GPS tracking platform processes thousands of data points per second maintaining real time map and WebSocket updates.

- Geofencing Engine. Created flexible geofencing system supporting custom zones. Administrators define customer locations, service areas, and restricted zones. The tracking system triggers automated alerts when vehicles enter or exit geofences.

- Driver Management. Implemented comprehensive driver scoring and driver behaviour analytics. The truck tracking platform calculates safety scores based on multiple factors. Managers access detailed reports identifying improvement opportunities. Video streaming integration enables reviewing incidents remotely.

- Fuel Analytics. Built sophisticated fuel monitoring and fuel theft alerts using CAN bus and OBD II data. The system compares expected fuel consumption with actual usage. Anomaly detection algorithms identify theft, leaks, or unauthorized refueling automatically.

- Compliance Automation. Developed ELD and IFTA compliance for USA regulations meeting FMCSA standards. The GPS fleet tracking system tracks driving hours automatically. Reports exports CSV PDF generate regulatory submissions with single clicks.

- Security Framework. Established robust privacy and security measures protecting sensitive data. Role-based access controls limit information visibility appropriately. Encryption protects data in transit and at rest. Video streaming access requires proper authorization and audit logging.

- Enterprise Integration. Built comprehensive API integrations with ERP and TMS systems. The fleet tracking system synchronizes with dispatch, billing, and maintenance platforms. Real-time data flows between systems eliminating manual data entry.

- Reporting and Analytics. Created extensive reports exports CSV PDF capabilities. The truck tracking platform generates customizable reports on utilization, costs, safety, and compliance. Automated report distribution keeps stakeholders informed.

outcome

Real-Time Fleet Visibility and 40% Cost Reduction

- 40% operational cost reduction. Fuel monitoring and fuel theft alerts identified savings opportunities. Route optimization through GPS tracking reduced unnecessary mileage. Predictive maintenance using CAN bus and OBD II data decreased repair costs. The tracking system delivered substantial ROI.

- 35% improvement in driver safety. Driver scoring and driver behaviour analysis reduced incidents. Video streaming capabilities enabled targeted coaching. Insurance premiums decreased based on improved safety records. The truck tracking system enhanced overall fleet safety.

- 50% faster dispatch decisions. Real time map and WebSocket updates provided instant fleet visibility. Dispatchers assigned jobs based on actual vehicle locations. Geofencing alerts enabled proactive customer communication. Response times improved significantly.

- 100% ELD compliance achievement. Automated ELD and IFTA compliance for USA operations eliminated violations. Reports exports CSV PDF simplified audits. The GPS fleet tracking platform met all FMCSA requirements. Administrative burden decreased by 60%.

- 30% reduction in fuel costs. Fuel monitoring and fuel theft alerts identified waste. The tracking system tracked idling and inefficient routes. Drivers modified behaviour based on feedback. Fuel efficiency improved across operations.

- Complete fleet visibility. Real time map and WebSocket updates provide instant location data for all 500+ vehicles. The tracking platform eliminates communication gaps. Geofencing capabilities ensure route compliance automatically.

Related cases

Articles you may also like

Top Logistics Technology Trends Reshaping the Industry in 2026

EDI in Logistics: How to Develop EDI Software to Make an E-Switch?

3PL Warehouse Management System: Why Choose a Custom SaaS WMS for Your Warehouse

Best Trucking Software to Consider: Custom vs Off-the-Shelf

Best Trucking Dispatching Software: Custom vs Off-the-Shelf

AI Route Planning: Must-Have Automation & Optimization Practices

![Generative AI in Supply Chain Management: [Use Cases & Solutions]](/img/articles/generative-ai-supply-chain-solutions/img01.jpg)

Investing in Generative AI Supply Chain Solutions: Use Cases & Challenges

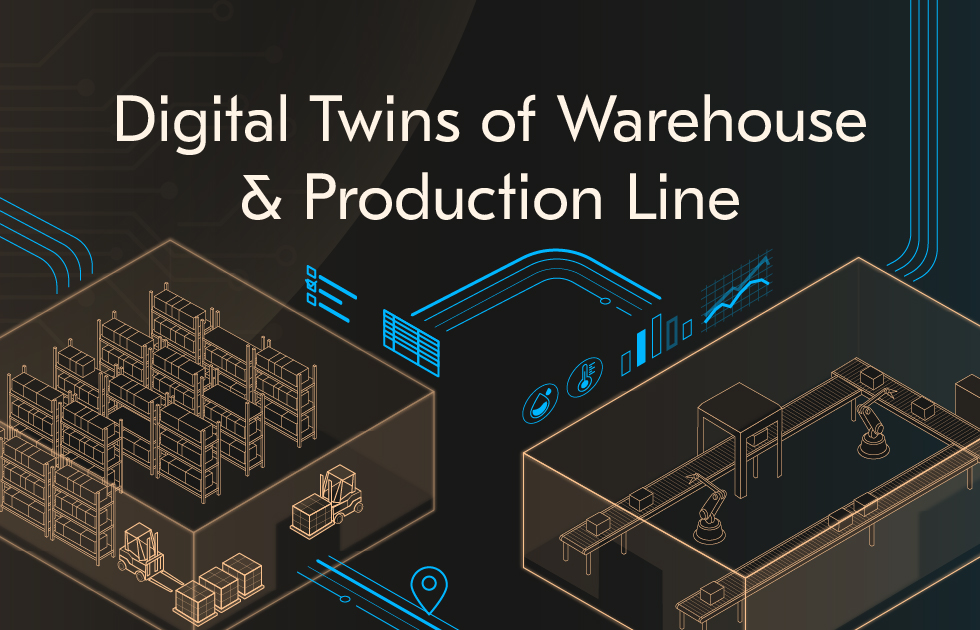

Digital twins of the warehouse and production line: modeling, telemetry and payback KPIs

![AI in Warehouse Management: [Benefits & Use Cases]](/img/articles/ai-in-warehouse-management/img01.jpg)

Why & How to Employ AI in Warehouse Management: Applications & Success Cases

![IoT for Supply Chain Businesses: [6 Use Cases Included]](/img/articles/iot-for-supply-chain-management/img01.jpg)

IoT for Supply Chain Management: Use Cases, Benefits & Real Examples

Embracing IoT in Transportation and Logistics to Boost Supply Chain Visibility

![ᐉ Airport Operations Management Solftware [2025 Guide]](/img/articles/airport-operations-management/img01.jpg)

Airport Operations Management Software to Modernize Your Business in 2025

![ᐉ Big Data in Logistics: Key Benefits [5 Real Use Cases]](/img/articles/big-data-in-logistics/img01.jpg)

Big Data in Logistics: Key Benefits & 5 Real Use Cases

![ᐉ Mapbox vs. Google Maps [Choosing a Map API]](/img/articles/map-api/img01.jpg)

Mapbox vs. Google Maps: Choosing a Map API

![Machine Learning in Logistics and Supply Chain [7 Use Cases Included]](/img/articles/machine-learning-in-supply-chain-and-logistics/img01.jpg)

Adopting Machine Learning in Supply Chain and Logistics for Successful Automation

![Transport App Development [A 2025 Guide for Startups & Businesses]](/img/articles/transportation-app-development-guide/img01.jpg)

Transportation App Development Guide for Businesses: Benefits, Features & Case Studies

![ᐉ Blockchain in Logistics [Key Benefits & Real-Life Use Cases]](/img/articles/blockchain-implementation-in-logistics/img01.jpg)

Blockchain in Logistics: Key Benefits & Real-Life Use Cases

![Blockchain for Supply Chain Management: [Benefits & Use Cases]](/img/articles/why-and-how-to-employ-blockchain-in-supply-chain-management-tips-and-success-stories/img01.jpg)

Why and How to Employ Blockchain in Supply Chain Management (Tips & Success Stories)

![Predictive Analytics for Supply Chains in 2025: [Benefits & Applications]](/img/articles/predictive-analytics-in-supply-chains/img01.jpg)

Why Use Predictive Analytics in Supply Chains? Advantages, Use Cases & Solutions

![Fleet Fuel Management System [Complete Guide]](/img/articles/build-a-fuel-management-system/img01.jpg)

How to Build a Fleet Fuel Management System [Complete Guide]

![A Sustainability Transportation Guide: [Best Practices & Use Cases]](/img/articles/sustainable-transportation-practices/img01.jpg)

Sustainable Transportation Practices: Why Invest in Renewable Energy

![ᐉ Logistics Customer Portal Development: [2025 Guide]](/img/articles/logistics-customer-portal-development/img01.jpg)

Logistics Customer Portal Development: Step-by-Step Guide

![Transportation Telematics System: [Benefits, Challenges & Use Cases]](/img/articles/the-power-of-telematic-systems-in-transportation-benefits-challenges-and-use-cases/img01.jpg)

The Power of Telematic Systems in Transportation: Benefits, Challenges & Use Cases

![ᐉ Uber API Integration: [Step-by-Step Guide & Use Cases]](/img/articles/how-to-integrate-uber-api/img01.jpg)

Uber API Integration: A Complete Guide with 7 Benefits & Examples

![Big Data in Supply Chain: [9 Real Use Cases Included]](/img/articles/big-data-in-supply-chain-real-world-use-cases-and-success-stories/img01.jpg)

Big Data in Supply Chain: Real-World Use Cases and Success Stories

![6 Use Cases of AI in Transportation and Logistics: [2025 Edition]](/img/articles/ai-in-transportation/img01.jpg)

Use Cases of AI in Transportation & Logistics: Are They Relevant for Your Business?

![IoT in Fleet Management: [Use Cases, Trends & Case Studies]](/img/articles/employing-iot-for-fleet-management-benefits-use-cases-and-success-stories/img01.jpg)

Employing IoT for Fleet Management: Benefits, Use Cases & Success Stories

![Last-Mile Delivery Optimization: [Key Strategies in 2025]](/img/articles/last-mile-delivery-solutions-optimize-logistics-for-better-customer-satisfaction/img01.jpg)

Last-mile Delivery Solutions: Optimize Logistics for Better Customer Satisfaction

![Load Planning Software: [Features, Types and Benefits]](/img/articles/load-planning-software-features-types-and-benefits/img01.jpg)

Load Planning Software: Features, Types and Benefits

How to Develop a GPS Tracking Software for Real-time Vehicle Tracking

![Multi-Carrier Shipping Software: [8 Use Cases & Key Benefits]](/img/articles/multi-carrier-shipping-software-a-guide-to-enhancing-shipping-efficiency/img01.jpg)

Multi-Carrier Shipping Software: a Guide to Enhancing Shipping Efficiency

How to Build Custom Fleet Management and Maintenance Software

![Transportation Management Software Development [2025 Guide]](/img/articles/transportation-software/img01.jpg)

Transportation Management Software Development — A Detailed Overview

![How to choose the Best Transportation Management Software [2025 Guide]](/img/articles/best-transportation-management-software/img01.jpg)

How to Choose the Best Transportation Management Software: Custom vs. Off-the-Shelf

![Warehouse Automation Systems [8 Benefits for Your Business]](/img/articles/warehouse-automation-systems/img01.jpeg)

Warehouse Automation Systems: Technologies Taking Warehousing to the Next Level

How to develop a logistics document management system (case study included)

![Supply Chain Analytics Software [Key Features & Use Cases]](/img/articles/supply-chain-analytics-software/img01.jpg)

Employing Supply Chain Analytics Software for Efficient Workflows — Key Features & Use Cases

![The Best Route Optimization Software to Employ in [2025]](/img/articles/route-optimization-software/img01.jpg)

Custom vs. Off-the-Shelf Route Optimization Software: Which Serves You Best?

![Logistics & Shipping APIs Integration Guide [2025]](/img/articles/logistics-and-shipping-apis/img01.jpg)

A Guide to Integrating Logistics and Shipping APIs to Optimize Your Supply Chain Business

![Cloud Computing in Logistics and Supply Chain [2025 Guide]](/img/articles/cloud-computing-in-logistics-and-supply-chain/img01.jpg)

Cloud Computing in Logistics and Supply Chain: Use Cases Included

![ᐉ Warehouse Management Systems Development [2025 Guide]](/img/articles/warehouse-management-systems/img01.jpg)

Warehouse Management Systems Development: Empowering Real-Time Tracking and Visibility

Chatbots in Logistics & Transportation: Benefits & Use Cases

Logistics & Transportation Software Modernization: Best Practices and Lessons Learned

How Software for Freight Brokers Increases Business Efficiency and Profitability: Real-World Examples

Logistics App Development: Building a Product That Will Help Your Business

![Logistics Management System [2025 Guide]: Use Cases Included](/img/articles/logistics-management-system/img01.jpg)

Why A Logistics Management System Is A Must For Successful Supply Chain Operations

Supply Chain Management Software System: Its Features, Benefits, and How to Integrate a Suitable One

How to Turn Custom Freight Forwarding Software to Your Advantage

![Shipping Management System Development ☑️ [2025 Guide]](/img/articles/shipping-management-system/img01.jpg)

How to Automate the Shipping Process with a Shipping Management System

Guide of How to Integrate e-AWB for a Freight Forwarder

Why It Pays to Build Dispatch Management Software

How to Build Vehicle Routing Software to Earn More and Drive Less?